Alpha Pro Defoamer

$29.99

Air trapped in concrete will make foamy concrete that feels light, insubstantial, and weak. Using a good defoamer in your concrete countertop mix will help improve the density and strength of the concrete.

Alpha ProTM - Materials you can trust.

Air trapped in concrete will make foamy concrete that feels light, insubstantial, and weak. Using a good defoamer in your concrete countertop mix will help improve the density and strength of the concrete.

How Defoamers Work:

Defoamers don't make air that's trapped in the concrete magically go away. They work by destabilizing foam generated in the concrete that forms during mixing. Common ingredients that can create foam are polymers, superplasticizers, and pigments.

Defoamers help prevent the foam from forming in the first place, so air that gets whipped into the concrete during mixing won't form foam.

Foam (think of shaving cream or shampoo) is just lots of tiny air bubbles, and tiny air bubbles get stuck on sand grains, fibers and inside thick, stiff concrete. Defoamers pop those tiny bubbles to form larger ones.

Larger air bubbles have a better chance of escaping because they can force their way up and out of a mix, but that mix must allow those bubbles to rise and escape on their own.

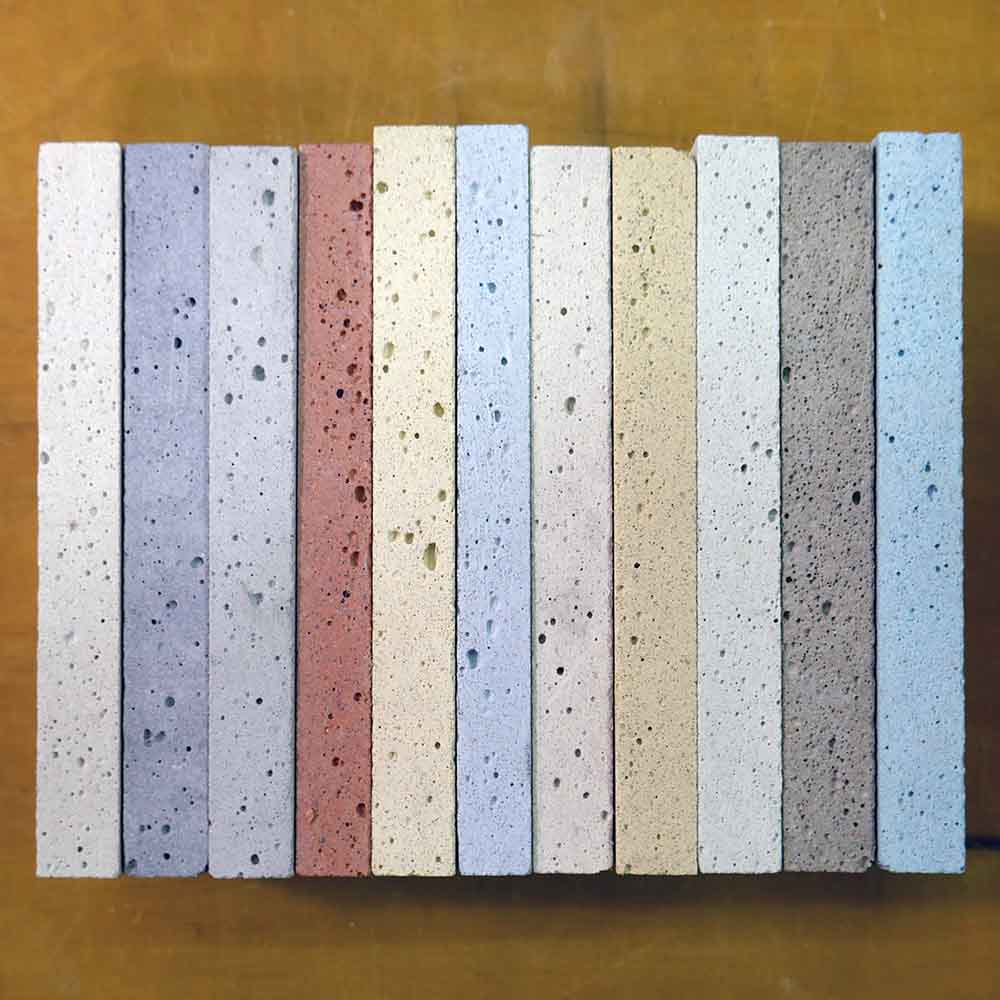

- Foamy concrete made without defoamer

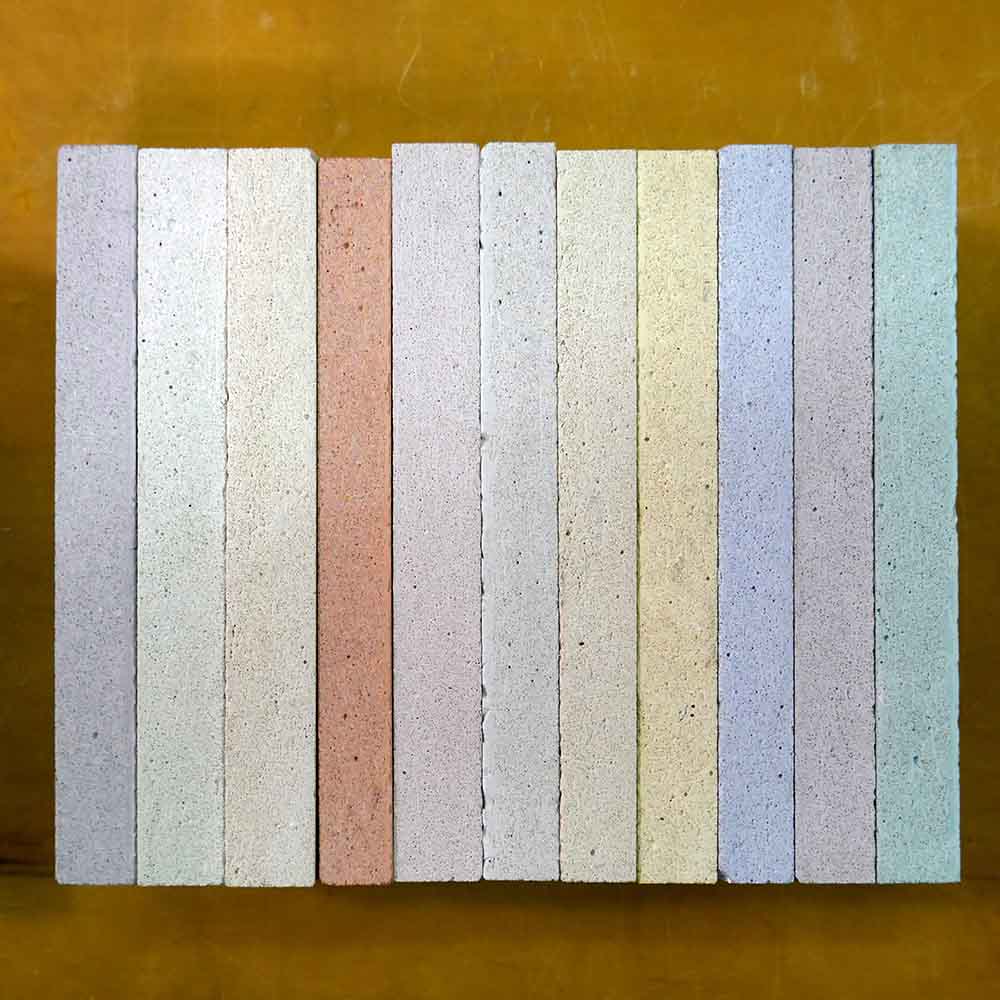

- Dense concrete made with the exact same mix design except Alpha Pro Defoamer was added

- The concrete in all of the above samples uses the exact same GFRC mix design and ingredients, except the dense samples used Alpha Pro Defoamer at a 0.1% or 0.2% dose.

- The foamy concrete samples have densities that range from 110 lbs/cubic foot (pcf) to 122 pcf.

- The dense concrete samples have densities that range from 135 pcf to 141 pcf.

- All the samples were fluid and direct cast with some vibration.

Watch Alpha Pro Defoamer in action:

The Importance of Fluid Concrete:

Defoamers can't get rid of all of the air, and if the concrete is too stiff they won't get rid of any of the air. Because of how they work, defoamers are most effective at removing entrapped air when the concrete is very fluid. Therefore, defoamers are best when used in tandem with a powerful superplasticizer such as Alpha Pro Fluidizer. Thick, stiff concrete won't release air because the concrete itself is a paste, not a fluid. Bubbles won't rise in a paste.

If you are making GFRC and compaction rolling the backer, this will not get rid of air bubbles. Compaction rollers merely align fibers; they are not effective at removing air bubbles.

(In commercial GFRC production, the high energy sprayers used for both mist and backer coats are effective at purging air, and defoamers are not necessary. However it is unlikely that any concrete countertop maker has the level of sprayer capable of purging air.)

Polymers and Foam:

Some GFRC polymers are notorious for causing foamy concrete. For example, the liquid polymer Forton VF-774. If you use Forton in your GFRC, we recommend buying Alpha Pro Defoamer in approximately the following proportions to your other ingredients:

- 1 - AR glass fibers (one 44 lb bag)

- 2 - Forton polymer (two 5 gallon buckets)

- 2 - VCAS pozzolan (two 50 lb bags)

- 6 - Alpha Pro Defoamer (six 333 g jars)

Alpha Pro Polymer does not cause foamy concrete, however you can add additional Alpha Pro Defoamer if you experience any foam or air bubbles due to your mixing process or equipment.

Dosage Rate of Alpha Pro Defoamer:

- Dose as a percentage of total cementitious weight (cement + pozzolan)

- Suggested starting dose: 0.1%

- Dosage range: 0.05% to 0.2%

- Defoamers have a narrow range of effectiveness, and overdosing can actually increase air content and weaken the concrete, so more is not better. Experiment with your mix to find the dosage that works best.

How to Mix:

- Defoamers are designed to be added at the beginning of mixing. Mixing is what whips air into the concrete and therefore can cause foam. They are less effective when added at the end of mixing.

- Pre-blend Alpha Pro Defoamer into your dry ingredients before mixing.