If you’re wondering about the importance of glass fibers in GFRC just think about the name for a minute. Glass fiber reinforced concrete – without the fibers all you have is concrete. These alkali resistant glass fibers give GFRC its strength and make it an ideal choice for a variety of applications including concrete countertops.

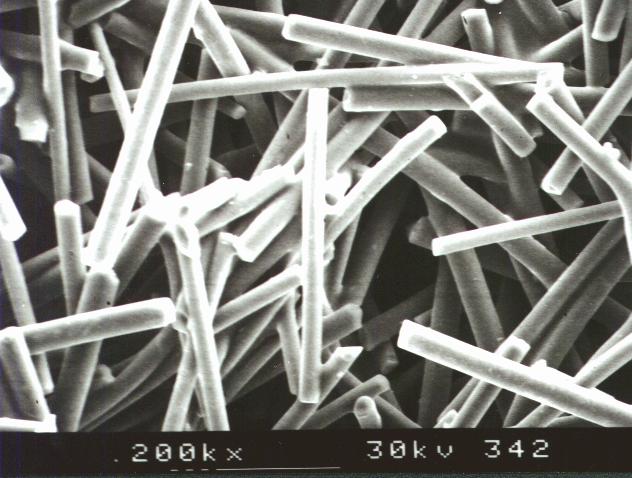

According to Wikipedia.com, “[g]lass fiber reinforced composite materials consist of high strength glass fiber embedded in a cementitious matrix. In this form, both fibers and matrix retain their physical and chemical identities, yet they produce a combination of properties that can not be achieved with either of the components acting alone. In general fibers are the principal load-carrying members, while the surrounding matrix keeps them in the desired locations and orientation, acting as a load transfer medium between them, and protects them from environmental damage.”

GFRC utilizes both concrete and strong AR glass fibers. Both possess benefits on their own, but when combined they become something amazing. Let’s take a look at the important role fibers play in GFRC.

AR glass fibers for GFRC

Why Fibers?

One of the benefits of GFRC is its tensile and flexural strength. The tensile strength helps GFRC to resist pulling apart forces while the flexural strength helps it to resist bending. The glass fibers and the high polymer content of GFRC provide these unique properties that are essential to a long lasting concrete countertop. Rather than using steel for reinforcement, GFRC relies on these glass fibers to prevent cracking and breakage. Reinforcement is essential any time you create a concrete countertop, and GFRC uses fibers to create this reinforcement.

This nine minute video, while it addresses steel reinforcing, will help you better understand the importance of reinforcement in general when constructing a concrete countertop:

Tips for Using Fibers in GFRC

Making GFRC isn’t as simple as just adding some fibers to your concrete mix design. There are many important considerations to remember. Here are a few:

- Amount of Fiber Present– GFRC relies on a high load of glass fibers. Without sufficient fiber the concrete will be unable to resist cracking and breakage when faced with a high tensile load. Fiber content varies, but is at least 3% of the total mix weight. Some mixes go as high as 10% fiber content. The more fiber present the stronger the GFRC, but increased fiber does lead to decreased workability and even to compromised compaction.

However, decreased fiber leads to the worse problem of less strength. Some concrete countertop teachers recommend only 2% fibers. I’m not sure what the motivation behind this is, but 2% is not sufficient. 3% is the minimum.

- Orientation of Fibers– Orientation of the fibers in the mix is also important. Truly random fiber orientation means more fiber is needed since many of the fibers will be pointing in the wrong direction. See below for

Some concrete countertop teachers recommend creating a fluid backer mix and pouring it into the forms, effectively an “SCC” backer mix. This should not be done, as it results in random fiber orientation. See below and read this article for more information about why this is problematic.

- Method of Reinforcement Used– There are three different levels of reinforcement used in general concrete and GFRC. Each type carries different benefits.

Level 1: Random 3-D Reinforcing

This type of reinforcement occurs when fibers are mixed into the concrete and the concrete is poured into forms. The fibers are evenly distributed throughout the concrete and point in every direction. Typically only 15% of the fibers are oriented in the proper direction requiring very high fiber loads. This level of reinforcing is very inefficient requiring large amounts of fiber for lower levels of reinforcement. This should not be used for GFRC.

Level 2: Random 2-D Reinforcing

In this level of reinforcing concrete is sprayed onto a form using special equipment that chops and adds the fiber during the spraying process. Spray-Up GFRC is an excellent example of this type of reinforcing. Typically 30% to 50% of the fibers are optimally oriented. This can also be achieved by placing thin layers of backer and compaction rolling each layer. This method is more effective than 3-D reinforcing, and is the recommended method for either hand-placed or sprayed-on GFRC backer coat.

Level 3: 1-D Reinforcing

The final level of reinforcing, one-dimensional reinforcing, is the most effective method available because it uses the least amount of reinforcing material to resist tensile loads. All reinforcing is placed in the tensile zone, or the area that needs the extra strength, reducing the overall amount of reinforcement needed. This method is used to create structural concrete beams with steel reinforcing. When creating a concrete countertop slab, the bottom of the slab is the tensile zone, as you saw in the video. Steel in precast concrete is an example of 1-D reinforcing.

Scrim in GFRC is another example of 1-D reinforcing. Scrim is a glass fiber mesh used to give extra strength to GFRC, in addition to the fibers. Although the scrim does provide targeted 1-D reinforcing in critical areas, you still need fibers throughout the backer coat to provide tensile and flexural strength throughout.

When it comes to GFRC glass fibers are essential, but as this article clearly illustrates there is more than one way to add those fibers in. The method you select will determine how much fiber is needed and how strong your finished concrete countertop will be.