Integrity PowerPack

Price range: $99.99 through $4,299.50

Integrity PowerPack is a high-performance concrete admix that delivers exceptional strength, workability, and durability while minimizing shrinkage and cracking – the ideal, cost-effective solution for professionals who need consistent, pro-grade results without shipping heavy cement and sand.

Take control of your mix with Integrity PowerPack.

Every project is unique, and you need an admixture for concrete countertops that works the way you do. Integrity PowerPack is the ultimate high-performance admix designed for professionals who demand flexibility without compromising quality. PowerPack is the admix version of our all-in-one mix PowerBlend. PowerPack gives you the freedom to choose your own cement and aggregates, so you can create the perfect mix for every job—whether it’s GFRC, ECC, or a custom blend tailored to your vision.

Built on the same advanced technology as PowerBlend, PowerPack delivers exceptional strength, workability, and durability while reducing shrinkage and cracking. It’s also an efficient, cost-effective solution for international and large-scale projects—eliminating the need to ship heavy cement and sand while ensuring you get consistent, professional-grade results every time.

Stop working around limitations. Make YOUR concrete with Integrity.

What Integrity PowerPack Does

PowerPack has exactly the same ingredients as PowerBlend, minus the sand and Portland cement. So you get the same powerful dry curing polymer, defoamer and pozzolan blend as well as the same benefits of stronger, faster, denser concrete while saving you time and money. Added benefits of PowerPack are savings on shipping of bulk sand and cement and control over your sand and cement. Use decorative, coarse or black sand instead of white. Use CSA cement instead of Portland cement. The choice is yours.

Properties of Integrity PowerPack

Strength:

Following are the strength test results for PowerBlend. These strengths should be very similar for both PowerPack and PowerBlend. The values may vary for PowerPack because of the variety of sands and cement brands you might use.

At 0.30 w/c and 2.5% AR glass fibers:

Compressive strength:

- 1 day: 6812 psi

- 7 days: 8706 psi

- 28 days: 11014 psi

Flexural strength:

- 1 day: 1339 psi

- 7 days: 1723 psi

- 28 days: 2188 psi

Coverage:

Some manufacturers state their coverage at 1 inch thick, even though this is not a typical thickness. However, for comparison:

- One 30 pound bag of PowerPack will make 294 pounds of concrete that covers 26 square feet at 1 inch thick.

- The same amount of concrete (294 lbs) will cover 34.6 square feet at 3/4" thick.

Cost:

- At the per bag price of $99.99, this equates to $2.89 per square foot for 3/4" concrete or $3.85 per square foot for 1" concrete.

- At the pallet price of $85.99 per bag, this equates to $2.49 per square foot for 3/4" concrete or $3.31 per square foot for 1" concrete.

PowerPack goes further than other admix blends. For example, one other admix's 30 pound bag costs slightly less than PowerPack. That other admix will make 188.2 pounds of concrete that covers 14.6 square feet at 1 inch thick. This equates to $5.82 per square foot. Therefore, that other admix is MORE expensive than PowerPack.

When choosing a blended admix product, don't be fooled by a per bag price. Understand the real coverage and yield of the product in order to make a fair comparison. And of course consider quality and performance first.

Cementitious Material:

If you are dosing pigments or various admixtures, you need to know the amount of cementitious material in your mix.

- Each bag of PowerPack contains 25.70 lb (11.657 kg) of cementitious material (pozzolans).

- We recommend adding 97.25 lb (44.114 kg) of Portland cement to each bag.

- This results in a total cementitious material per bag of 122.95 lb (133.771 kg).

How to Use Integrity PowerPack

Mix Design:

Here is a white concrete countertop mix recipe for GFRC using 1 bag of Integrity PowerPack:

- 1 bag of Integrity PowerPack (30.00 lb)

- 122.95 lbs of sand

- 97.25 lb of Portland cement

- 36.88 lb of water (0.30 water-cement ratio)

- 7.36 lbs of 19mm UltraFibers AR Glass Fibers (2.5% dose)

- Add a tiny amount of UltraFlow superplasticizer as needed. (1 lb of UltraFlow will treat up to 530 lbs of SCC/direct cast concrete, which uses about 54 lbs of PowerPack = 1.8 bags.)

This makes:

- About 34 sq ft of concrete at 3/4" thick, or

- About 25 sq ft of concrete at 1" thick.

Shopping List:

PowerPack:

To calculate how many bags of PowerPack you need for a project:

- Determine the square footage

- Decide how thick you are making the concrete.

- Divide the square footage by 34 if you are making the concrete 3/4" thick or by 25 if you are making the concrete 1" thick.

For example, suppose you need to make an 85 sq ft kitchen countertop:

- Square footage: 85

- Thickness: 1"

- Bags needed: 85 / 25 = 3.4 bags, so buy 4

If you instead decided to make this countertop 1.5" thick, you would need to multiply 3.4 bags by 1.5 = 5.1 bags (so purchase 6 bags).

Fibers: Buy UltraFibers here.

According to the mix formula above, each bag of PowerPack requires 7.36 lbs of UltraFibers.

For example:

- In the above scenario of 4 bags of PowerPack, you would need 4 * 7.36 lbs = 29.44 lbs of UltraFibers.

- UltraFibers come in 2.2 lb bags (1 kg) and 44 lb bags (20 kg).

- Divide 29.44 by 2.2 = 13.8 bags of UltraFibers. You can buy 14 bags, or in this case it is more economical to buy a single 44-lb bag of fibers.

UltraFlow: Buy UltraFlow here.

- If you are planning to use fluid concrete for SCC/direct casting, divide the number of PowerPack bags by 1.8 to determine how many 1-lb jars of UltraFlow to buy.

- If you are hand packing a stiff mix, you will need far less UltraFlow.

See the UltraFlow page for detailed dosing instructions.

Bulk Purchasing:

It is far more economical to buy in bulk. Here are the proportions of UltraFibers and UltraFlow for half pallets and pallets of PowerPack:

Half Pallet of PowerPack (25 bags = 750 lbs) makes about 853 sq ft at 3/4" thick and requires:

- 184 lbs of UltraFibers

- 15.4 lbs of UltraFlow if you're making flowable concrete. 15 lbs will probably suffice.

Pallet of PowerPack (50 bags = 1500 lbs) makes about 1707 sq ft at 3/4" thick and requires:

- 368 lbs of UltraFibers (double the amount for a half pallet)

- 30.8 lbs of UltraFlow (double the amount for a half pallet)

Mixing Instructions:

Concrete made with PowerPack is most effective when pre-blended into your sand before adding your mix water.

For flowable concrete, always chill your concrete using ice to achieve a concrete temperature of 55°F to 65°F. See below for determining ice quantities needed.

- Dry blend together all of the sand, PowerPack, plus pigments and UltraFlow as needed.

- Add all the mix water plus ice to the sand + admixtures. Mix until all dry material is wetted out.

- Gradually add all the cement and blend until fully mixed.

-

- Add about 1/3 to 1/2 of the cement and blend until mix wets out.

- Add half of the remaining cement and blend further until mix wets out.

- Add remaining cement and blend until all dry ingredients are incorporated.

- Scrape the bucket and the mixing paddles well, then mix continuously on medium to high speed for no less than 2 full minutes. This is most important for flowable SCC/direct cast mixes.

- Make sure that any ice has fully melted before proceeding to the next step.

-

- Add fibers last. Gradually add the fibers to prevent clumping and mix slowly to prevent whipping air into the mix. Ensure the fibers are fully wetted out and well dispersed throughout the mix. Do not mix on high speed.

Adding Ice to Chill Your Mix:

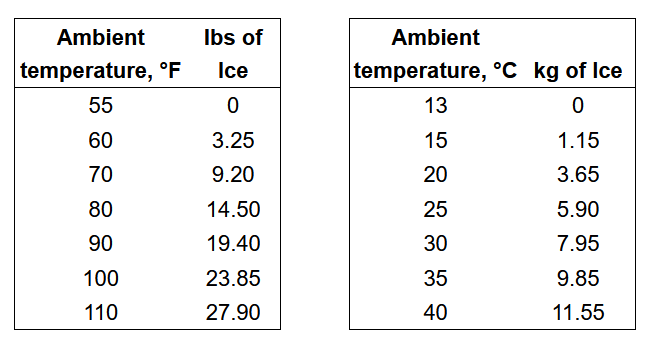

Chilling your concrete greatly increases working time and improves flowability. It is important for direct cast or SCC concrete. Your concrete should be between 55°F snd 65°F.

Replace some of your mix water with ice by equal weight. The chart below is for each bag of PowerPack, and it assumes all mix ingredients except ice are at ambient temperature.

For example:

- If your shop temperature is 90°F and you are using a 1/2 bag of PowerPack, replace 19.40 / 2 = 9.70 lbs of your mix water with ice.

- If your shop temperature is 85°F, calculate the ice amount for 80°F and 90°F and use an amount of ice about halfway in between.

The amount of ice does not need to be precise. Only the total weight of water and ice combined needs to be exact. For example:

- Suppose your mix formula calls for 36.88 lbs of water total, and based on the chart, you are going to use 14.50 lbs of ice to chill your mix.

- You are replacing 14.50 lbs of water with ice.

- Therefore you will use 36.88 - 14.50 = 22.38 lbs of water.

- You will use 22.38 lbs of water and 14.50 lbs of ice in your mix.

Q & A

Integrity PowerPack

Integrity PowerPack

Please see this article about sand sizes for GFRC: https://concretecountertopinstitute.com/free-training/best-sand-for-gfrc/

Reviews

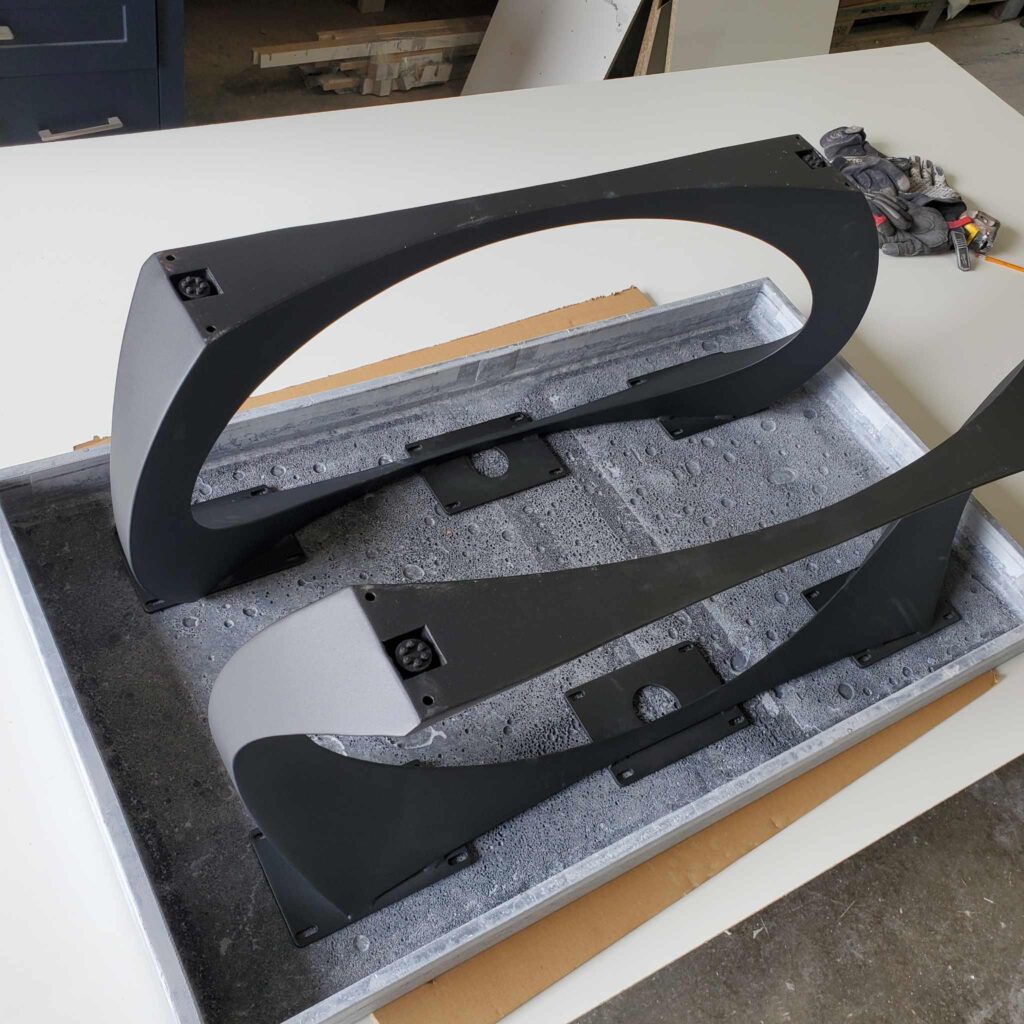

Customer Images

5 star 100% 4 star 0% 3 star 0% 2 star 0% 1 star 0%

We used Integrity products to create this beautiful white with gray marble kitchen bar top. Using Integrity Alphapro Ultra Adpack allowed us to cast concrete 34″ thick, keeping the weight down to a minimum and allowing the concrete to be strong enough to be flipped and processed 24 hours after casting. Ultraflow dry superplasticizer worked fantastically. Integrity’s superplasticizer worked amazingly, as the mix started out mixing dry and after little less than a minute of mixing, mix went wet and flowed extremely well in the mold, allowing entrapped air to be released. We also used Integrity’s Ar glass fibers, they worked great, there wasn’t any trouble with mix chocking up and we had no fibers showing. Using Integrity products allows us to customize our mixes to fit each project individually, making each piece a truly one-of-a-kind!!

I’ve tried a variety of their products, including Integrity Ultra Adpack, Integrity products, UltraFlow Superplasticizer, Ultra Dense Defoamer, and GFRC Fibers – and they are all absolutely amazing! However, the Integrity Ultra Adpack has truly been a game changer, especially for artisans like myself.

The quality of this product is outstanding. From the very first use, it was clear to me that Integrity Ultra Adpack is a top-of-the-line product. You can tell The Concrete Countertop Institute has put a lot of thought and care into creating a product that is not only highly functional but also incredibly user-friendly. It has made my work significantly easier, and the detailed, precise instructions provided not just for the Adpack but for all their products, make the entire process seamless.

If you haven’t used Integrity Ultra Adpack, Omega/Ovation Sealer, or any of their other products, I highly recommend them. You won’t be disappointed. These products are absolutely worth the investment and will quickly become your go-to essentials. I promise!

I’m excited to continue exploring their product range and can’t wait to try more from The Concrete Countertop Institute soon!

Working with CCI has been an absolute game-changer for my business. From the very start, their team demonstrated a remarkable level of expertise, professionalism, and dedication to helping us achieve our goals. What truly sets CCI apart is Jeff’s expertise in the field, their products and customer service. They truly care about the success of their customers.

Their team consistently goes above and beyond to ensure that every detail is taken care of, always keeping us informed about new products. Whether it’s Jeff’s deep industry knowledge, their quick responsiveness CCI exceeds expectations in every area.

Hi Jeff, I used the Alpha pro admix with great results. Most perfect concrete I’ve ever cast,…in like 5 minutes!

Love the product