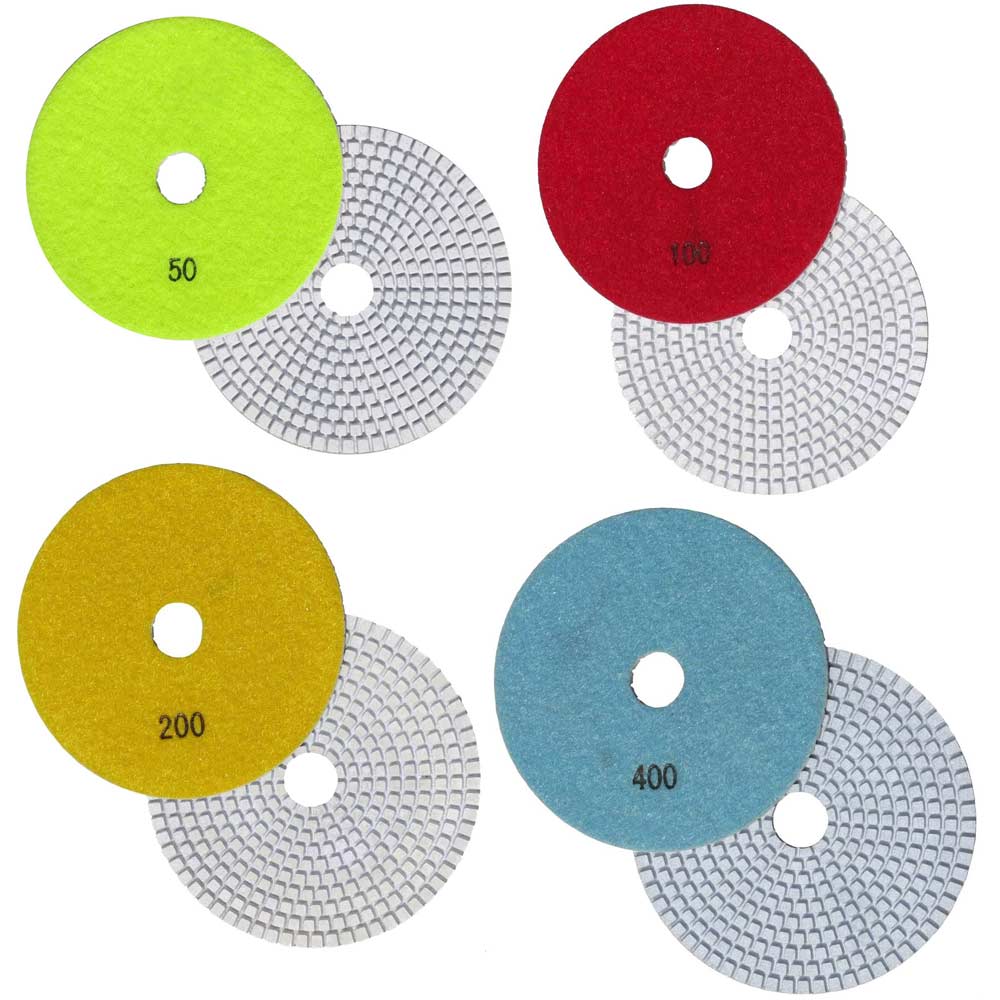

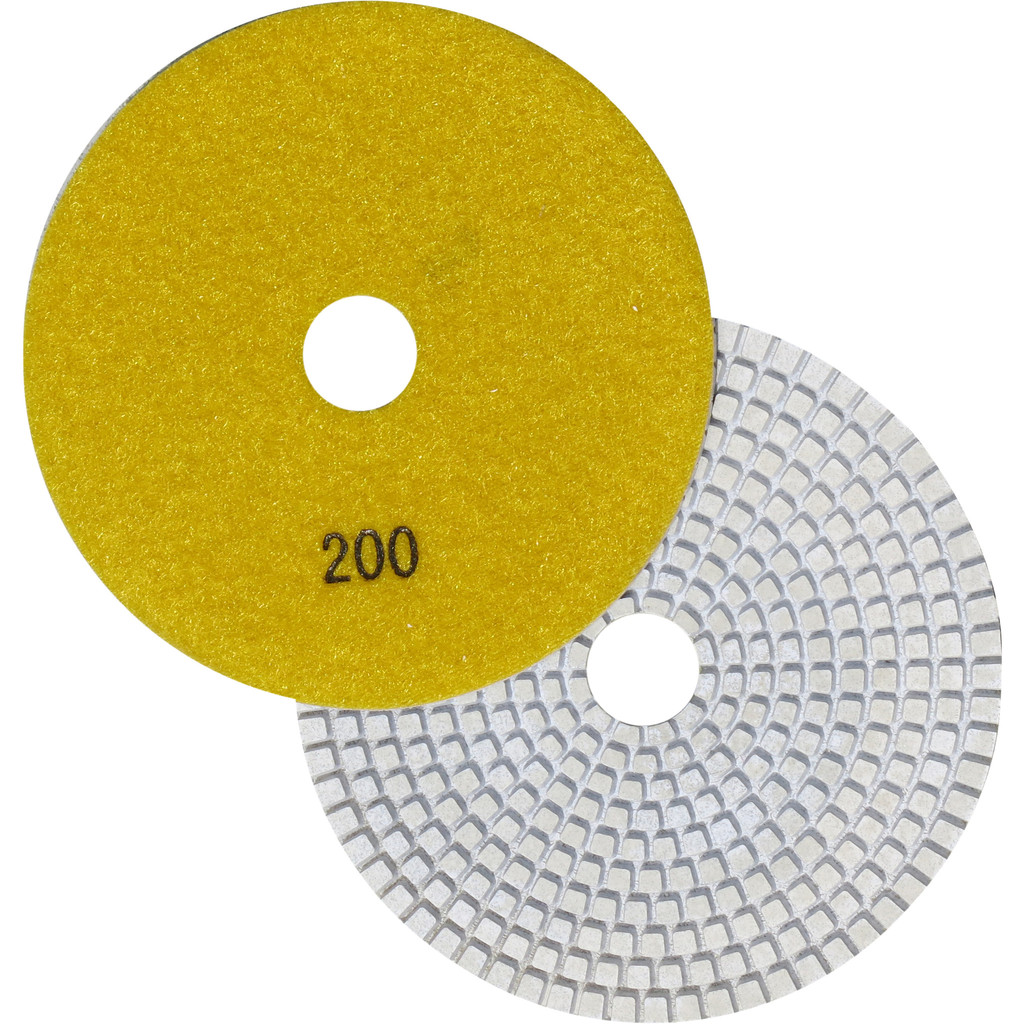

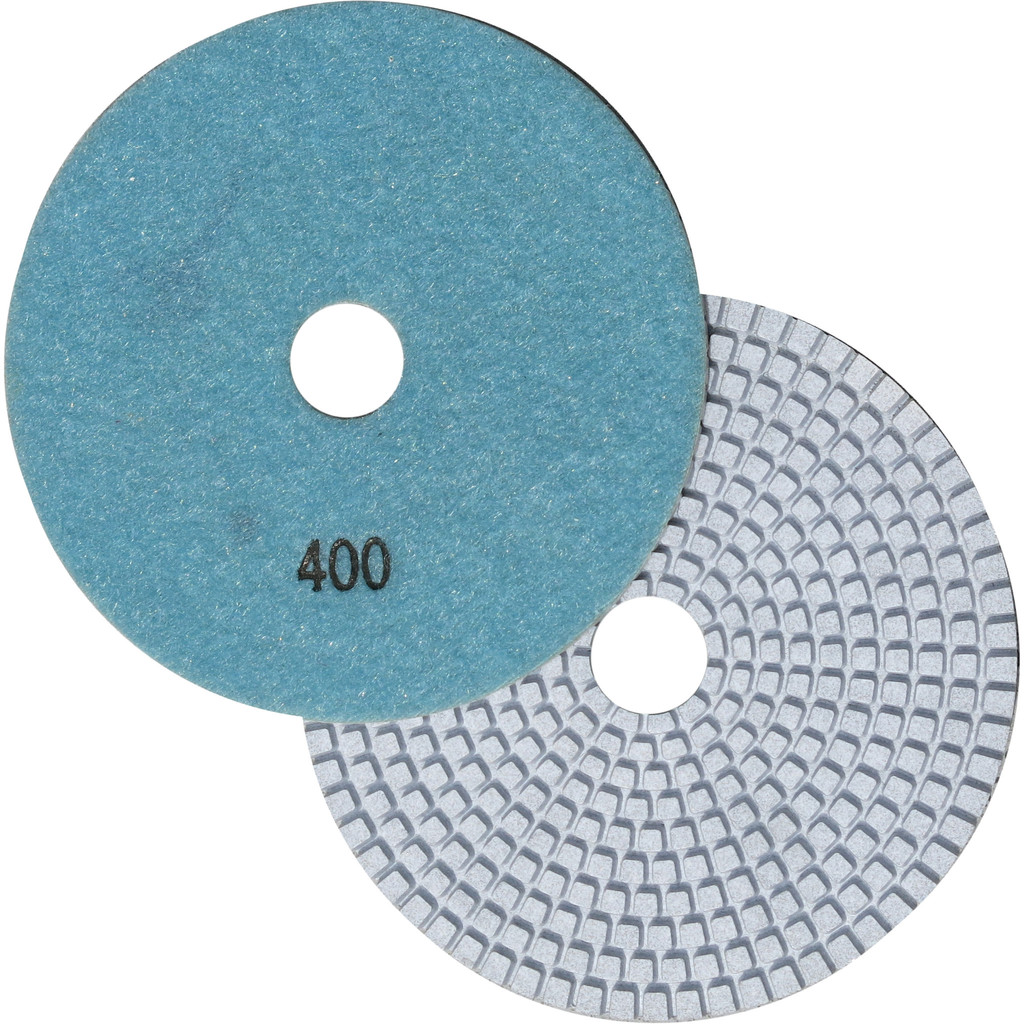

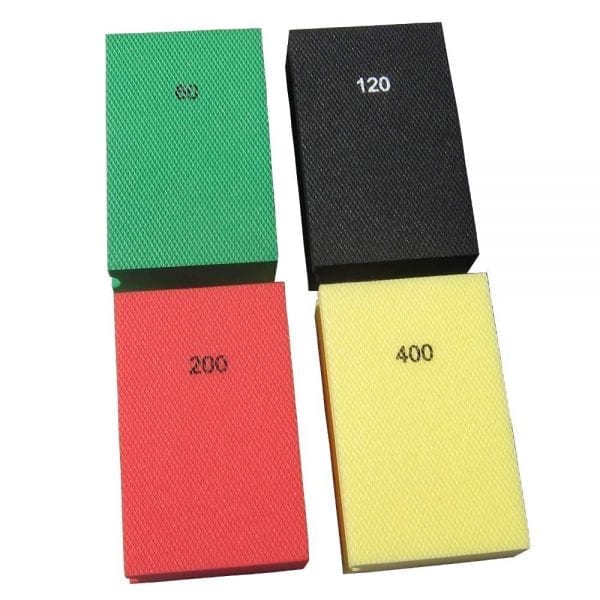

5 Inch Diamond Polishing Pads for Concrete Countertops

Price range: $24.99 through $107.06

CCI’s 5″ Diamond Polishing Pads are the ultimate wet grinding solution for concrete countertops, engineered with high diamond concentration, flexible long-life design, and ideal slurry channels to deliver fast cutting, swirl-free finishes, and professional results every time.

These 5" diamond pads for wet grinding have all the features you need for concrete countertops:

- High concentration of diamonds for faster cutting

- Narrow gradation of diamonds for a swirl-free surface

- Thick enough for long life

- Thin enough to be flexible

- Ideal channel design to eject slurry and prevent clogging

- Ideal resin binder for long life without glazing

CCI's diamond resin polishing pads and diamond hand pads were designed specifically for the concrete countertop industry. These are not pads borrowed from the granite industry that work well on stone but not so well on concrete, nor are they bargain-basement lookalike disks offered because they provide a generous profit margin to the seller. They're designed and tested by CCI, the most knowledgeable and experienced force in the concrete countertop industry.

These are the best discs on the market. Period.

They give you everything you've been looking for in a premium polishing disk: versatility, fast cutting, quality finish and long life.

- Unlike thick, rigid pads, they don't curl and wear unevenly. The thin pad is flexible, so you can hone flat surfaces and curved sinks with ease.

- Numerous, wide grooves channel slurry out from under the disc, reducing clogging, premature pad wear and scratches from the cuttings.

- Tightly graded, premium industrial diamonds cut fast but leave a smooth, scratch free surface.

Watch the video below. It shows how the design of the CCI diamond pads makes them the best diamond pads for concrete countertops:

How to Use Diamond Pads for Concrete Countertops

These pads are for wet use only. We do not recommend dry grinding. In fact it cannot be used if you are going to apply a coating sealer. Read this article to understand why.

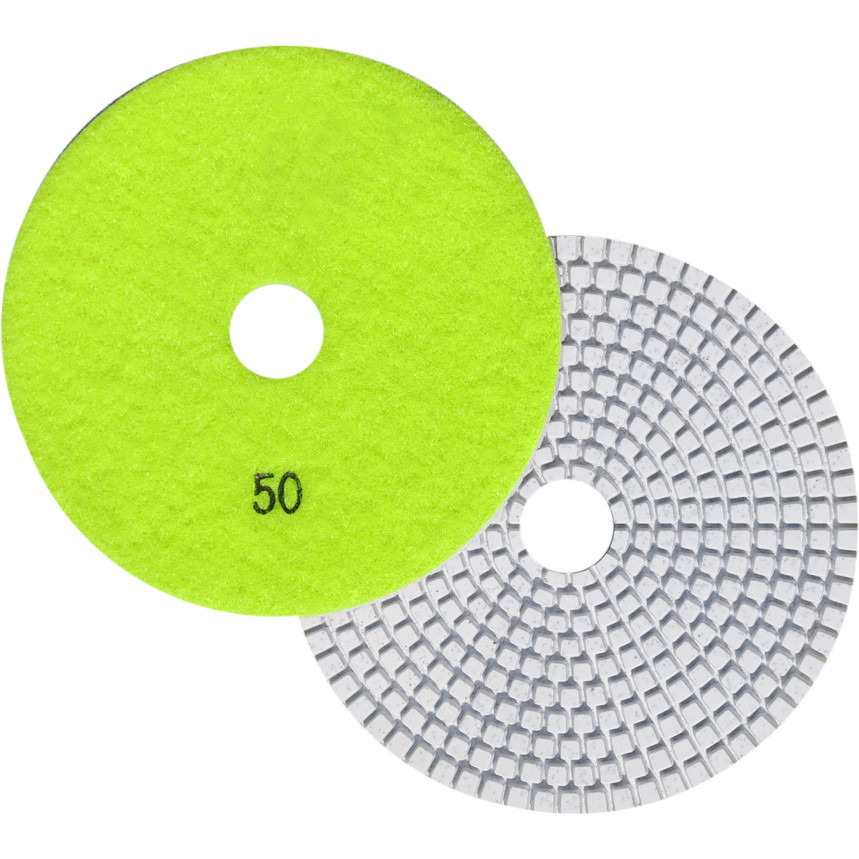

- Use the 50 grit pad after a turbo cup for exposed aggregate.

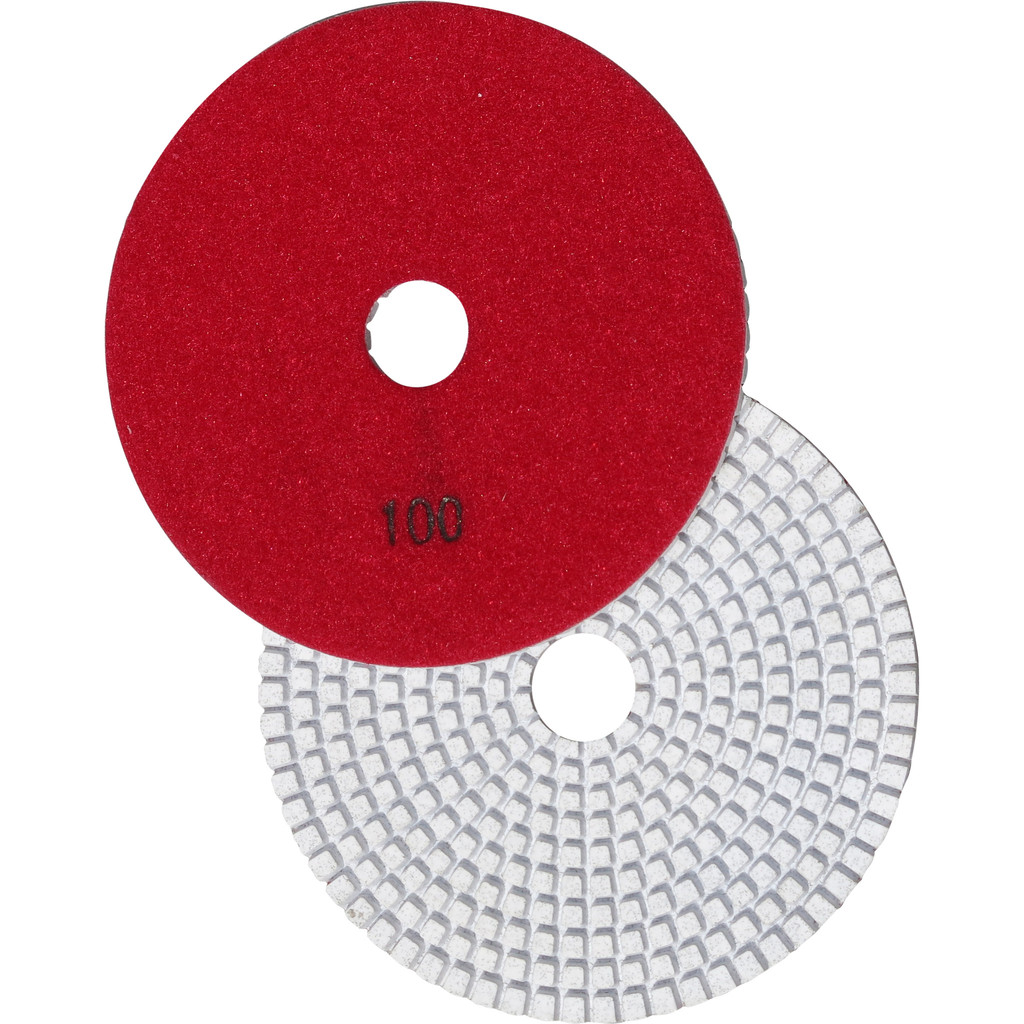

- Use the 100 grit pad after the 50 grit pad. It is generally not a grit you would start processing with.

- The 200 grit can follow the 100 grit pad. Or, it is often used as a starting point if only light honing is performed. (If you are applying a topical coating sealer such as Ovation or Omega Concrete Countertop Sealer, do not progress past this grit. Doing so may make the surface too smooth for the sealer to adhere. It is also unnecessary because the sealer will provide the finished surface texture.)

- The 400 grit pad is optional. Ovation and Omega Concrete Countertop Sealer will adhere to 400 grit surfaces, but 200 grit is usually sufficient. You may need to continue to the 400 grit pad depending on the desired surface quality.

- We do not recommend polishing to a high sheen, which is why we no longer offer higher grit pads. You can control the sheen of your concrete with the sealer. For example, Omega has a matte sheen, whereas Ovation is available in satin or gloss sheens. You can combine the two sealers to control the sheen.

Visit our diamond polishing page for more information and articles.

Why do we offer only one diamond pad choice, when everyone else offers so many?

When you polish with a diamond pad, it has only one job to do, and that's to grind/hone/polish the concrete as quickly as possible and leave the best finish. That's exactly what these pads do. You don't need several different types of diamond pads, you need only the best.

How do other diamond pads compare?

Here are examples of other diamond pads that exhibit uneven wear, warping and cracking. Some have binders or channel designs that don't work well for concrete versus stone, and some are too thick or too flexible.

Q & A

5 Inch Diamond Polishing Pads for Concrete Countertops

5 Inch Diamond Polishing Pads for Concrete Countertops

Please follow the epoxy manufacturer's surface prep instructions. We don't sell or use epoxy on concrete, so we cannot provide guidance or make recommendations.

For wet polishers it's 3000 to 4000 rpm, or as fast as your wet polisher will go.

Yes, CCI 5" diamond pads will fit any 5" random orbit sander with a velcro face, regardless of brand.

Generally diamond pads last a long time, but that depends on how they're used. They don't go bad sitting around. I have diamond pads that are almost 20 years old.

If you are using a true wet polisher with the correct amount of water (just enough to flush the cuttings out from under the diamond pad and also to keep it cool) on concrete that is not too soft or too rough, then each pad should last for several hundred square feet or more. Coarser pads tend to be used on rougher material, so they get used up the fastest. If you use the diamond pads for 8 hours a day, every day, then they'll wear out faster than if you only use it a few hours a week.

The diamonds are infused in the resin that makes up the pad. You use it until the fabric/velcro backing starts to show.

Reviews

Customer Images

5 star 100% 4 star 0% 3 star 0% 2 star 0% 1 star 0%

I bought these when I realized I needed to resand my countertops and the cheap one I bought on Amazon were wearing down quickly. These look barely worn after several rounds of sanding. The Velcro will wear out before the diamond surface.

These are the most durable and correctly rated for grit pads that I have ever used. Other brands of pad are so variable in quality that I would reluctantly ever use amother source.

We have concrete counter tops in the kitchen. They are about 15 years old. The UV finished yellowed and cracked. I scraped off the UV and then sanded. The discs worked great. I finished the tops with wax. They look great.

It works very well. At first touch, it seems not to be abrasive at all but after using it for a few minutes, the roughness can be felt. It doesn’t take as much material off as you might expect for 50 grit, but it does the job. Better slow than fast! Fast can be done with a grinder – this is for finish work.