Don’t even think about using non-shrink precision grout to create concrete countertops. While its properties may make it seem like an ideal choice at first glance, avoid the temptation to use it. I’ll explain why…

One reason that people are tempted to use non-shrink precision grout (also called NSPG) on concrete countertops is its name. “Non-shrink” could have some big advantages. Secondly, its compressive strength is often very high. Typical compressive strength values are 8,000 psi to 14,000 psi at 28 days, with 1 day strengths in excess of 3,000 psi. Other factors are its availability and reasonable price.

However, “non-shrink” is a misnomer. This article explains why and what applications are appropriate for NSPG. Concrete countertops are not one of them.

What is Non-Shrink Precision Grout?

NSPG is an all-sand mix characterized by good flowability, very high compressive strength and under ordinary use no net shrinkage. Working time is often short, with set times of about an hour or so, but this can vary with different formulations.

NSPG becomes “non-shrinking” due the use of Type K expansive cement. Type K cement expands soon after setting. The “non-shrink” properties are a bit of a misnomer and can be confusing. All concrete shrinks to some degree or another over time as it dries out. However, the net shrinkage that occurs is what matters in the normal applications of NSPG. The expansive cement expands for a short period of time after it sets. This initial positive expansion exceeds the anticipated shrinkage that will occur over time when the NSPG is used for what it is intended. Thus there is still some expansion remaining. The concrete first expanded a lot and then shrank a bit less, so the net result is nearly no shrinkage. Hence “non-shrink”.

NSPG is used when setting machinery bases, generators, mills, presses, compressors, etc., structural grouting of precast columns, steel columns, and anchoring of sign posts, anchor bolts, and dowels. It is essentially a structural filler in these applications.

In the ordinary applications that NSPG is intended for, its expand-then-shrink behavior is tolerable. However for countertops, the fact that the NSPG shrinks at all is not tolerable. We will explain this later. First, let us consider the question: Why does “non-shrink” precision grout shrink at all?

How Does It Work?

Most NSPG is a blend of expansive cement, finely graded sands and other proprietary ingredients. The proportions of cement to sand are much higher than in ordinary concrete. When used as a structural filler, this blend creates a very creamy, highly workable (sometimes pourable) mix with high cementitous content (paste). When concrete shrinks, only the paste shrinks, so a higher paste volume results in higher shrinkage. NSPG attempts to counteract the anticipated shrinkage by first expanding.

NSPG and Concrete Countertops

This is part of the problem with using NSPG for countertops. With the oridnary applications that NSPG is intended for, usually not much of the grout’s surface area is exposed to the air, so drying occurs slowly. With a countertop made out of NSPG, there is a huge amount of surface that can dry out. Thus any early expansion that would normally counteract the inevitable shrinkage is overwhelmed by the excessive amounts of shrinkage caused by rapid and continuous drying.

Countertops are large, flat beams with large amounts of surface area exposed to the air, so drying becomes a serious issue. As concrete dries and loses moisture, the capillary tension created by the water in the fine pores causes volumetric shrinkage. It is the loss of internal water that causes the shrinkage. The longer the concrete is allowed to dry, the more shrinkage will occur. For larger pieces of concrete, drying shrinkage can continue for years. Even very thin pieces of concrete will continue to shrink over time, as will be seen below.

Testing

To investigate the shrinkage potential for the non-shrink grout, I cast several 5’ long, 1” thick beams with reinforcing steel extremely close to one face (the cast side).

The beam design was chosen to exaggerate the curling tendency of each mix. Long, thin slabs exhibit more curling than short, thick slabs. Shrinkage causes curling, either from differential drying or differential restraint, or both. Differential drying occurs when one side of a slab dries out faster or more than the other side. The side that is drier shrinks more, so the slab curls towards the dry side. Differential restraint occurs when one side of a slab is allowed to shrink more than the opposite side. The reinforcing steel keeps its side from shrinking much, whereas the side that has no reinforcing shrinks more. When both factors are working together, large amounts of curling occurs. (This is why it is important to moist cure slabs properly so that they don’t curl.)

The beams were first allowed to moist cure for 3 days before being stripped and then set out to air dry, reinforcing side down against a smooth impervious surface. These conditions are considered very extreme and were selected to maximize the amount of curl that would occur.

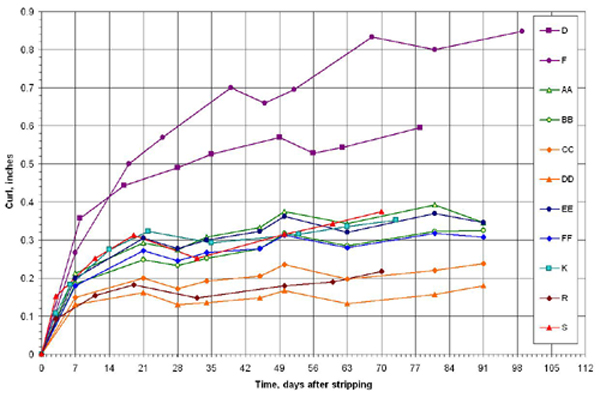

Curl measurements were periodically taken on the back side (the smooth cast side). A 6’ straightedge and a dial caliper were used to measure the growing gap between the slab ends and the straightedge. All measurements are changes relative to the slab geometry measured immediately after stripping.

In the graph, samples “D” and “F” are a commercial non-shrink precision grout mixed and cast according to the manufacturer’s instructions. Sample “D” had a water to cement (w/c) ratio of about 0.30, and sample “F” had a w/c of about 0.43.

Because the non-shrink precision grout had a higher cement to aggregate ratio than all of the other mix designs, the slabs made with the NSPG exhibited the most amount of curl, even though the w/c ratios were similar, or even lower than, the other mixes.

Two things become clear: first, lowering the w/c ratio is only part of solution to reducing shrinkage (and thus curling). Secondly, shrinkage (and therefore curling) occurs for a long period of time after casting, and that significant amounts of curling occur even after 14 days.

Better mix designs (those that minimize shrinkage tendencies through careful aggregate gradation and optimum cement contents) show lower overall shrinkage and stabilize sooner than the NSPG, which has large amounts of cement paste and a narrow range of fine aggregates. For these reasons and all of the reasons explained in this article, I do not recommend NSPG for use in concrete countertops.