This article concludes the discussion of stiff versus fluid concrete countertop mixes (started here), with the final three differences.

Difference #3: Mix Design

Stiff Mixes

Stiff concrete mixes can be either all-sand mixes (no coarse aggregate) or coarse-aggregate based mixes. Generally they are all-sand mixes due to the ease of spreading and packing a fine-grained clay-like concrete. Coarse aggregate makes the mix “chunky”, often making hand-packing difficult or uncomfortable.

All-sand mixes have far more surface area, so require more cement paste. But the fine grained nature of sand inhibits movement due to the increased particle friction generated from many times more contact points. All-sand mixes are typically stiff, zero slump. It is possible to make an all-sand mix fluid with a combination of a powerful superplasticizer and strong vibration, but this is rarely done.

Fluid Mixes

Fluid concrete mixes are generally based on coarse aggregate. Aggregate based mixes are more easily made fluid because of the large amount of coarse aggregate in the mix. Pound for pound, coarser aggregate has less surface area than fine sand. A mix that has less surface area requires less cement paste to coat the particles, and any excess paste in the mix acts as lubricant, allowing the particles to move past each other more easily.

Difference #4: Forming Techniques

Stiff Mixes

Because of the nature of stiff mixes, watertight forms are not necessary. As such, careful caulking of the seams isn’t required. If the form edges are caulked, it is because a cast rounded edge is desired instead of grinding a rounded edge. Forms should be tight, but the added step of caulking is not necessary.

Fluid Mixes

It’s a different story with fluid concrete. The forms must be watertight with fluid concrete because any leakage will result in discoloration of the concrete and loss of material.

Fluid concrete also requires that reinforcing steel be tied to the sides of the forms, since the steel will sink if simply placed in the form. However, it is very important not to pour the concrete over the steel. Doing so will result in ghosting. To prevent ghosting, either tie the steel after the forms are mostly filled with concrete, or very carefully pour the concrete through the holes between the steel, taking care not to pour onto the steel. Also, if the concrete is to be vibrated, the steel must be tied in place so that it does not move.

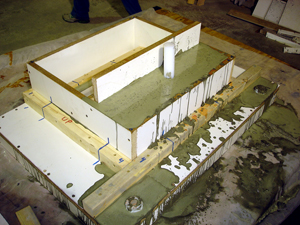

Comparison of Forms

Stiff mixes require less form work than fluid mixes when complex or 3 dimensional pieces are being cast. This is especially true for integral sinks cast into countertops. On the other hand ordinary flat countertop slabs use essentially the same forms for both stiff and fluid mixes.

Fluid concrete mixes need more complex forming for an integral sink.

Stiff mixes require less forming because the concrete is self supporting.

Difference #5: Casting Effort

Stiff Mixes

Stiff mixes take more effort to cast, and if care is not exercised in placement, air will get trapped between the concrete and the form. This results in large, shallow “craters” that often are on the order of 1/16”deep. The resulting surface is ugly and inconsistent in appearance, and it is difficult to repair by grouting.

Fluid Mixes

Fluid mixes are quick and easy to cast, as long as you take care with the reinforcing steel as noted in Difference #4: Forming Techniques.

Conclusion

As you can see, the choice of a stiff mix versus a fluid mix has many implications for all steps of the concrete countertop production process. Understanding the interplay of these implications is important for producing a high-quality concrete countertop.