Handling and transportation are risky operations. Too much time and effort goes into making a high quality concrete countertop to risk cracks or damage from improper transport. Keep these important tips and guidelines in mind:

- Transport on-edge, not flat

Concrete countertops are moved and transported in a vertical position, much like sheets of glass.

Concrete is strongest in a on-edge, vertical position. Beams are stiffest when they are oriented vertically, and they are the most flexible when they are flat. For example, floor joists and roof rafters are commonly made from 2x material set on the narrow edge, not set flat.

Small, compact slabs can often safely be transported flat (right side up) because they don’t deflect much. However, long slabs have a greater tendency to flex, and a sudden pothole or bump in the road could cause a large shock, overload the concrete and crack it. By orienting the slabs vertically, the deflection of such a deep, stiff beam is negligible. Therefore very low tension forces are developed, so the risk of cracking a slab is reduced tremendously.

- Never turn slabs upside down

Even with very small countertops, slabs should never be carried flat while upside down. Properly designed concrete countertops locate the primary reinforcing near the bottom, which is generally the tension side. If a countertop is turned upside down, it no longer has reinforcing on the bottom.

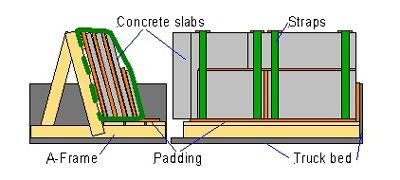

- Use an A-frame

When transporting slabs, use an A-frame to support and secure the slabs during transport. These frames are often made of galvanized steel rigidly welded to provide a sturdy structure. Sometimes homemade wooden frames are used too, but these must be made very sturdy and rigid to protect the countertops.

- Use padding such as moving blankets to protect and separate slabs from the frame and each other.

- Use straps or clamps keep the slabs from moving or shifting.

- Helpful equipment: Lifting straps, carry clamps, rolling carts, dollies, sawhorses

Individual slabs can simply be carried by two or more people, but special lifting straps and carry clamps that grab onto the edges of thinner slabs make handling safer and easier, especially for large and unwieldy slabs. Sometimes rolling carts or dollies are used too. You can place sawhorses along the path from your truck to the installation site to give you places to put down the slabs and rest periodically.