Some skills are easy to pick up through intuition, a little know-how and a heap of being able to figure things out on your own. Others, not so much. One thing that many people, even people with years of experience, struggle with is mold making for concrete countertops and other creations such as concrete sinks.

The possibilities for mold making are endless. You can add great, unique features to homes in which you’re already working, or you can create ‘carry-away’ products that can improve the value of someone’s home without the need for remodeling or reconstruction. Every fabricator should master the art of mold-making: it can make or break your business.

Here’s an excerpt from our 3-D Molds & Sinks textbook that will give you a little guidance on mold making. Part 1 of this article deals with basic mold-making concepts.

Molds are forms that duplicate (in reverse) some master shape that will be cast in concrete. For sinks, the master shape could be an existing sink, or it could be a mockup of the final concrete sink. For drain boards, the master shape may not exist, and the mold has to be constructed creatively to produce the desired final result.

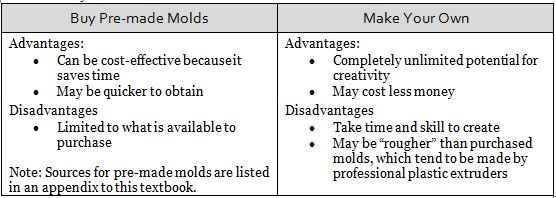

There are 2 ways to obtain molds:

Molds should be:

- Easy to make

- Durable

- Accurately reproduce the shape and texture desired

- Easy to remove from the concrete

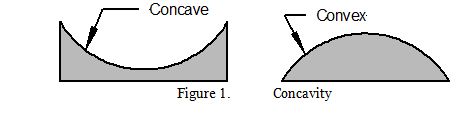

Mold Concavity

Concave means curved inward, like a cave. Convex is the opposite, a shape that sticks out.

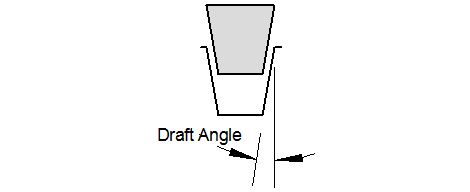

Draft Angle

The shape of the mold is an important consideration in determining what the mold is made of and the resulting complexity of the mold. In general, it’s best to avoid parallel sides and undercut areas where the concrete would key itself into the mold (or the mold would be locked into or around the concrete), especially if the mold is made out of a rigid material. There are ways around these situations, but it’s often best to avoid them in the first place.

In order for concrete to release easily from a rigid mold, the inside sides of the mold need to be angled. This prevents the mold from becoming locked into the concrete. The mold taper is called the draft angle.

The draft angle most commonly used when casting concrete is about 5 to 15 degrees, with 10 degrees being a comfortable average. Deeper or more rigid molds call for greater draft angles to ensure the cast part can be removed from the mold (or the mold from the part).

Figure 2. Draft angle for molds and forms.

Figure 2 shows a rigid mold with a wide opening and a narrower bottom. The wall’s draft angle allows the entire cast object (gray) to slip easily out of the mold.

Mold Types: Single-Sided and Double-Sided

Sinks, and virtually all 3-dimensional shapes, can be cast using either single-sided or double-sided molds.

A single-sided mold is used when only one side of the finished cast piece will be visible. The visible side is the side cast against the mold’s surface. Single sided molds are best suited for hand-packed concrete and GFRC. An example of this is a conventional, flat countertop form.

Single-sided molds are simpler to make, and they offer a wider flexibility in design and final cast appearance.

Variegated or hand-pressed concrete can be cast only in a single-sided mold, since it’s only possible to pack the stiff concrete against one side of the mold.

A double-sided mold uses an inner and outer mold, so both sides of the cast piece are finished and visible. Double sided molds are best suited for flowable wet casting methods where the fluid concrete is not self-supporting and thus needs a top cap to contain the concrete. An example of this is a vessel sink.

Double-sided molds are a bit more challenging, since an inner and an outer mold are necessary.

Read on for part 2 to learn about the best mold making materials.