Any material can be used for a concrete mold, provided it satisfies certain requirements. The material must be:

- non-porous

- non-reactive with concrete

- waterproof (or be protected from water)

- dimensionally stable and rigid so that the mold shape does not change during casting (or the combined mold liner plus mother mold must be rigid).

A mold that is reusable is advantageous but not necessary. Often a one-time use mold is satisfactory for an odd or very specialized shape that is not likely to be called for again.

The following sections detail the properties and advantages and disadvantages of various mold-making materials.

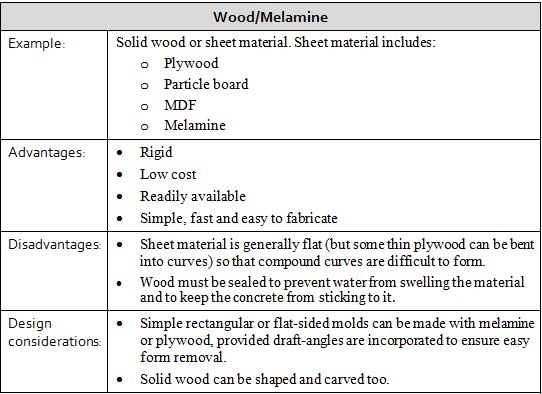

Wood/Melamine

Melamine is one of the most commonly used mold-making materials. The table below outlines several important points about melamine and other sheet materials.

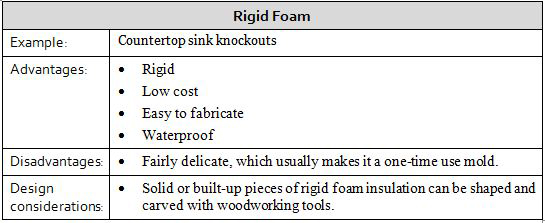

Rigid Foam

Rigid foam is often sold as rigid insulation or foam board. There are several types, the most common are:

- Molded Expanded Polystyrene (MEPS) foam board.

Often called bead board, it’s readily identified by the small foam beads (often white) that form the foam. This type of foam is less dense and has a low surface quality. Often this kind of foam needs to be coated with other smoother, more rigid materials.

- Extruded Expanded Polystyrene Foam Board (XEPS) foam board.

A denser, more rigid, solid closed-cell foam. XEPS can be cut, routed, shaped and sanded without the need for a coating. Typical insulation densities are 1.5 lbs./cubic foot. While soft and vulnerable to denting and damage, machined surfaces have a good surface quality.

Both MEPS and XEPS are vulnerable to solvents like acetone, xylene, toluene and MEK, and will dissolve from fiberglass polyester resin. Epoxy can be used to coat MEPS and XEPS without dissolving the foam. Brands such as Akemi and Touchstone work well; both are granite epoxies.

- Polyisocyanurate (polyiso) and polyurethane foam board.

Both are very similar and offer higher compressive strengths and better solvent resistance than polystyrene foam board. Often used with polyester resin and fiberglass.

Summary of rigid foam:

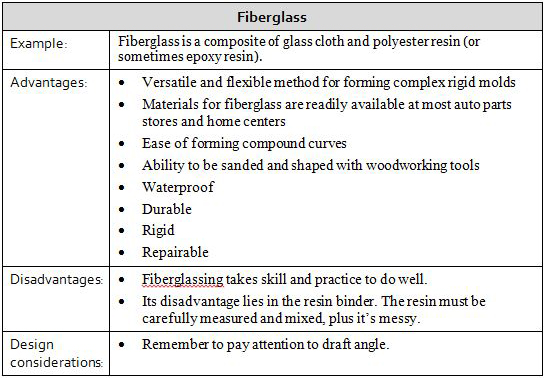

Fiberglass

The basics of fiberglass are:

Polyester auto body filler (Bondo® for example) is a great material for creating fillets, building up shapes, smoothing curves, tool marks or for general sculpting. It can be used alone, with plastics, fiberglass and other mold materials. It sands easily when mixed properly and allowed to cure.

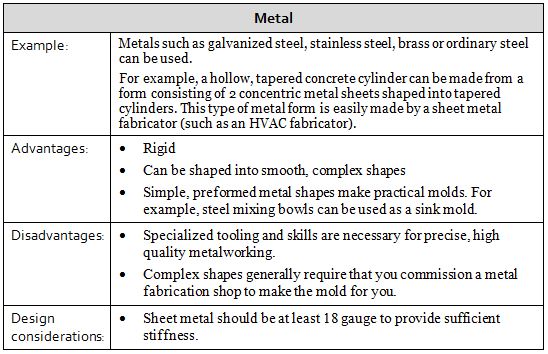

Metal

The basics of metal are:

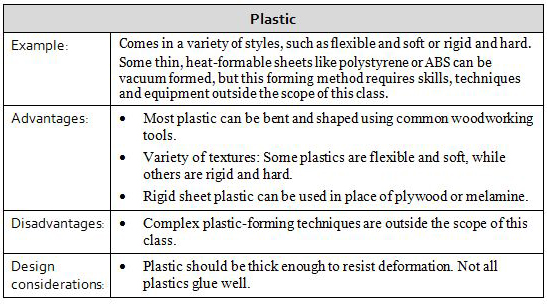

Plastic

There are a wide variety of plastics available. Many come in sheet, bar, rod or pipe form. The choice of plastic depends upon physical properties, price, availability and often workability. Below is a list of some common plastics and their properties.

- ABS (acrylonitrile-butadiene-styrene):

Tough, impact resistant. May be solvent welded with ABS cement.

- Acrylic:

Smooth surface for high surface quality molds. Often clear. May be solvent welded. Hard and rigid. Plexiglas® is a brand of acrylic.

- Polycarbonate:

Smooth surface, high optical clarity. Excellent impact resistance. Difficult to solvent weld. Hard and rigid. Lexan® is a brand of polycarbonate.

- Polyethylene:

Members of the polyolefin family with a wide range of properties. All are generally tough, slippery and easy to machine but difficult or impossible to solvent weld or glue. Includes LDPE (low density polyethylene), HDPE (high density polyethylene) and UHMW (ultra-high molecular weight polyethylene). UHMW has a coefficient of friction close to Teflon®. LDPE is softer and less rigid than HDPE or UHMW.

- Polypropylene:

Similar to polyethylene, it is hard, smooth and non-toxic. It can be heat welded but is very difficult to glue. It, like polyethylene machines well with woodworking tools.

- Polystyrene:

A versatile, low cost hard plastic that comes in thinner sheets. It’s fairly strong, rigid and easy to work with. Plastic models are often made of polystyrene. It can be heat formed and solvent welded.

- PVC (polyvinyl chlorine).

Rigid, type I PVC is strong, rigid and easy to solvent weld. It can be worked with common woodworking tools. PVC is a very versatile and easy to work with plastic. It’s an outstanding all-around choice.

Summary of plastic:

Concrete and Plaster

Concrete and plaster can also be used for molds. The Sinks & Molds textbook has many more details and examples of using plaster to create a mother mold for an integral sink and various parts of a vessel sink mold.

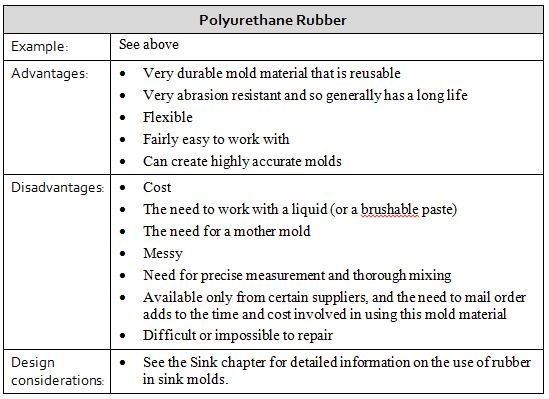

Polyurethane rubber

Polyurethane rubber is a two part casting material that has a variety of physical properties. Some of these properties are fluid viscosity (the thickness of the liquid rubber before it cures), cured rubber hardness, tear strength and other special properties like integral release agent. Certain properties like viscosity or hardness can be selected depending on the molding technique used.

Some rubbers are pourable while others are thick and are designed to be brushed on. This is a useful when applying the material to a vertical surface.

Generally polyurethane rubbers are two-part systems. They usually have a pot life of 15 to 60 minutes and cure within 16 hours. Often an accelerator can be added to decrease curing time.

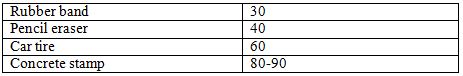

One of the key material properties is cured rubber hardness. Generally the softer the rubber, the easier it is to release the mold from a complex shape, but softer rubber is not as durable. As the hardness increases, the less flexible but more durable the rubber. At the extreme, stamps used for decorative concrete usually have a hardness of about 80 to 90. A Shore-A hardness of 60 is a versatile hardness with a good balance between flexibility and durability.

Some common materials and their Shore-A hardness values are listed below:

Summary of rubber:

The self-study course 3-D Molds & Sinks contains full details about rubber in sink molds.

Read on for part 3, where we will discuss mold removal tricks.