So you’ve made a mold, crafted your concrete creation, and now it’s time to get that creation out of the mold without breaking it, and if you’re using a reusable mold, without breaking the mold.

Flexible molds are easy. If you’ve designed the mold and the draft angle correctly, you can simply flex the mold and peel or wiggle it out of the concrete.

Rigid molds can present a challenge. The concrete actually creates a vacuum on the mold, holding it so tightly you might think you will never get the mold out without destroying it. Not if you have a few tricks up your sleeve. Try the following tricks for fiberglass or plastic molds, especially sink molds.

Method 1:

- Fill the inside of the rigid mold with ice and water.

- Wait until the mold shrinks, generally 5 minutes or so.

- Drain the ice and water, then pull the mold free.

Method 2:

- Remove the drain plug and fill the space with water.

- Replace the drain plug.

- Hit the top of the drain plug with a rubber mallet, being careful not to strike the sink mold.

- The hydraulic pressure will pop the mold out of the concrete, because water is an incompressible fluid.

- Repeat until the sink pops free.

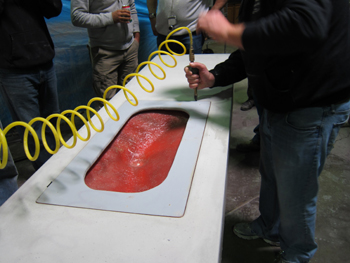

Method 3:

- Blow compressed air between the mold and the concrete. This may require a hole to be drilled in a part of the mold so that the air can get between the mold and the concrete. Often this hole is where the drain plug is.