Drying is an important process that must be managed and understood in order to avoid problems. At certain times drying is to be avoided, whereas at other times it is necessary. Understanding how temperature, dew point and humidity levels work together will shed light on how you can manage drying.

Concrete needs to stay moist in order for it to cure. But some sealers need the concrete to be dry in order for them to cure and stick properly. It’s a delicate balance. Temperature and humidity levels play a major role in whether your concrete or sealer cures properly, or whether your concrete stops curing, develops map cracking (or worse) or if your sealer has bonding and curing problems.

It’s well known that in hot conditions things dry out fast. So during the summer months (and for some of us summer temperatures have already arrived) it’s vital to make sure bare, exposed concrete that’s still curing stays moist. On the other hand, cold temperatures make it harder to dry things out. Cold concrete takes much longer to dry out because water does not evaporate as fast.

I will describe how drying is influenced by temperature, relative humidity and describe what the dew point is and how it relates to relative humidity.

Drying is also known as evaporation. The rate at which water evaporates depends upon several factors, including the temperature, relative humidity and air flow rate. Water evaporates very fast when it’s exposed to hot, dry fast moving air. Conversely water evaporates very slowly when it’s in cold, damp still air.

Temperature describes how much energy is available to drive evaporation. On a warm day more water can evaporate because there is more thermal energy available to do the work of evaporation. In contrast water has less available thermal energy to drive evaporation when it is cold out. Hence drying slows considerably when it’s cold.

Relative humidity is important because the more moisture that’s already in the air, the lower the rate at which water will evaporate and the less moisture that the air can hold.

Relative humidity is a measure of the current amount of water vapor in the air relative to the total amount of water vapor that can exist in the air at its current temperature, and is expressed as a percentage.

A relative humidity of 100% means the air cannot contain any more water vapor at that temperature, whereas a relative humidity of 50% means that the air only has only half as much water vapor as it can hold at the current temperature.

Dew Point is the air temperature at which the air is saturated with water vapor. Warm air can “hold” more water than cold air. When air at a given temperature can’t hold any more water it is fully saturated and is at 100% relative humidity. The air isn’t holding onto the water vapor. What’s being described is really the temperature when water vapor levels reach the saturation point.

Air flow rate is important, because as water evaporates, the layer of air above the water (or damp concrete) gradually becomes more saturated with water vapor. When evaporated moisture levels reach saturation drying essentially stops. Air flow increases the evaporation rate by “flushing” away the stagnant moist air above the concrete.

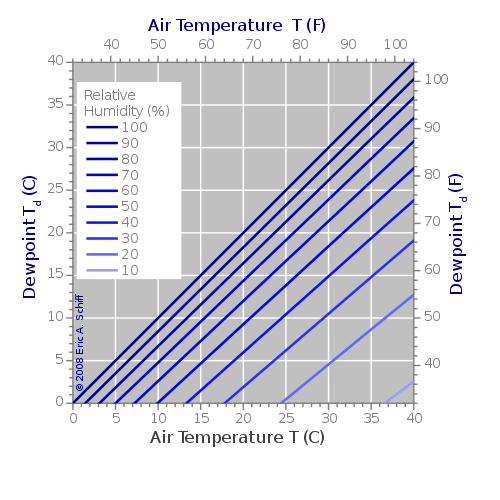

The following graph shows the relationship between air temperature, dew point temperature and relative humidity.

Moist Curing

Concrete needs to remain moist in order for it to cure. Generally the internal relative humidity needs to be above 80% to 85% relative humidity for hydration to take place.

Wetting the surface of bare concrete creates a barrier of water that prevents the moisture from inside the concrete from being drawn out when the surface moisture evaporates. The film of water on the surface is a relatively large reservoir that can evaporate without affecting the moisture within the concrete’s pores. Water on the concrete acts like a buffer.

When concrete is covered in plastic, the air trapped under the plastic quickly becomes saturated with water vapor. When this happens drying essentially stops.

When concrete dries out, the suction forces developed when water evaporates from the pores in the concrete can actually crush weak cement paste. The longer the concrete remains moist, the greater its strength and the greater the resistance to the suction forces. This means fewer cracks and less shrinkage and curling. Longer wet curing also reduces pore size, which means less moisture is available to evaporate and that the moisture has a harder time escaping out of the concrete.

Drying

Some sealers need concrete to be dry in order to stick properly. And some sealers will not cure properly if there is too much moisture in the concrete.

Temperature and relative humidity are important factors to pay attention to so that your concrete dries to the degree you need it to so that the all-important sealer performs the way you and your client expect it to.

If your shop is cold (like most shops are in the winter), the evaporation rate is slower, and because most shops have open sources of water in them (trench drains, wet grinding areas, etc.), the relative humidity is generally higher than outdoor conditions. These limit how much drying occurs. If your shop is at 100% relative humidity it doesn’t matter how long you “dry” the concrete. It won’t lose moisture and dry out because the air surrounding the concrete can’t hold any more moisture.

Remember: wet concrete doesn’t dry out in small, cold shops with still air. Hot shops with moving air that has a low relative humidity will cause rapid drying.

Happy concreting!