You know you need to weigh out ingredients for your concrete mix precisely, but did you know that scales can lie, and that cheap scales lie a lot?

Choosing a scale based on price alone can ultimately cost you hundreds or possibly even thousands of dollars. You may be using the wrong scale and not know it, because scales give you the illusion of precision when you don’t always have it. Digital readouts are very specific about what they display (it says it’s 7 grams!), but what you don’t know is that you may really have more or less material than you think (it’s really 6.8 grams, but the scale can only show that it’s 7). This can lead to problems, especially with colors. And making the wrong color concrete could mean re-doing an entire job.

How Digital Scales Work

Electronic digital balances (or just “scales”) are vital tools for measuring precise amounts of material, including aggregate, cement, water and pigments. Scales come in a variety of sizes, price ranges, capacities, levels of precision and cost. Choosing the right ones can save you money, time and give you more control over your concrete.

Balances/scales weigh an object by matching its weight against one or more reference weights. Mechanical balances use physical weights for direct comparison, whereas electronic balances store a calibration weight’s voltage signal in the electronics’ memory.

When a weight is placed on the digital scale’s weighing platform, a sensor called a load cell converts the force from the object being weighed into a voltage signal. This signal is then processed by the scale’s electronics to display the weight of the object in whatever units (grams, pounds, ounces, etc.) desired. The load cell and the electronics are the brain of the scale, and higher quality scales have better and more sensitive electronics.

Tools of the Trade

Often it’s necessary to use two or even three different scales when weighing out the ingredients for a batch of concrete. One scale (often a floor scale or a postal scale for packages) is used to weigh out heavier, bulk ingredients like sand and cement. And generally a smaller bench scale is used to weigh out smaller amounts of ingredients, like superplasticizer and pigments. This is because most scales have a limited weighing range that give the most accurate measurements. The range is defined by the scale’s capacity and readability (more on these later).

But there are times when very small quantities must be weighed out, often sub-gram amounts, and this can require a third, even more sensitive scale. These very sensitive scales are important when making color samples, as the quantities of pigments and other ingredients tend to be very small.

Capacity and Readability

The reason it’s necessary to use more than one scale is that scales have two important parameters: capacity and readability.

- Capacity indicates the maximum amount of weight the scale can safely measure

- Readability is the smallest division it displays.

The scale below has a capacity of 200 grams and a readability of 0.01 grams. (The label “d=0.01g” indicates the readability. Note also the 2 decimal places after the number.)

As another example, a postal scale may have a capacity of 150 pounds and a readability of 0.1 pound.

This type of scale would be a very good choice for measuring out sand, cement, gravel and other heavier, bulky materials for larger batches of concrete. However, it would be a poor tool for measuring out small amounts of pigments, because its readability (0.1 pound) is too large.

This is where a second, smaller scale becomes necessary. Just as with the larger scale, selection of the capacity and readability are important, so that the scale can do the job you’re expecting it to (and relying on).

Here are guidelines for your two essential scales:

- Your larger scale should be able to measure up to 100 pounds (or more) with a readability of 0.1 pound.

- Your smallest scale should be able to measure at least 400 grams with a readability of 0.1 gram.

Here are two examples to help you further understand readability:

- If a scale has a 0.1 pound readability, the smallest division displayed is one tenth of a pound (0.1). The scale won’t show anything smaller (like 0.03 pounds), since the scale cannot subdivide the readability any further.

- Likewise a scale with a readability of 1 gram will display readings like 5, or 25, or 133, but never 0.5 or 0.2, since the readability is limited to whole grams.

Other Factors

In addition to capacity and readability, some other scale parameters and features are important to consider:

- Price

- Quality

- Measuring range

- Ability to be recalibrated

As with anything else, lower quality often means lower price, and quality scales can be pricey. Good quality scales are accurate, stay accurate and can be recalibrated as needed.

Measuring Range

Measuring range is the difference between capacity and readability. For example:

- Larger measuring range: 2000 gram capacity and 0.1 gram readability

- Smaller measuring range: 1000 gram capacity and 1 gram readability

Generally scales with a large measuring range between capacity and readability are higher quality and will cost a lot more.

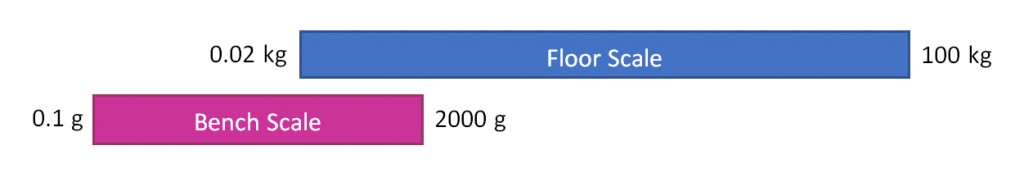

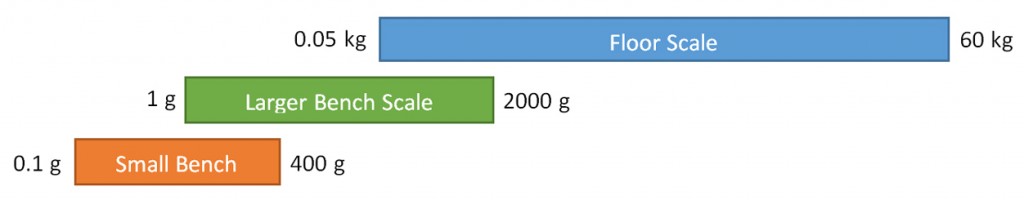

It’s convenient but not necessary to buy a scale with a broad measuring range, as a broader range means two scales can do the job of three, but those two scales may cost just as much (or more) than three quality scales with smaller measuring ranges. Here’s an example of two broad-ranged scales you might equip your shop with:

- A floor scale with a capacity of 100 kg and a readability of 0.02 kg (20 grams)

- A bench scale with a 2000 gram capacity and 0.1 gram readability

Another example of three very good smaller-ranged scales you might equip your shop with:

- A floor scale with a capacity of 60 kg and a readability of 0.05 kg (50 grams)

- A larger bench scale with a 2000 gram capacity and 1 gram readability

- A smaller bench scale with a 400 gram capacity and 0.1 gram readability

It’s important that when selecting scales, that the “overlap” between two scales is large enough to allow for accurate measurements within the overlap range.

For instance in the example above, the smaller bench scale has a capacity of 400 grams, which is much larger than the readability of the larger bench scale (1 gram), and the larger bench scale’s capacity is much larger (2000 grams) than the readability of the floor scale (50 grams).

In general you want the capacity of a smaller scale to be at least 20x the readability of the next larger scale. This is because when you weigh out material, the weight of the container counts against the total capacity of the scale, so the total capacity of the scale needs to be large enough to allow for both the weight of the container and the weight of the material. If the scale doesn’t have enough total capacity, then the larger scale must be used to weigh out the material, but in doing so you lose significant amount accuracy when weighing amounts close to the readability of a scale. More on this later.

Most low-cost “value-priced” scales (like postal scales or kitchen scales) offer good capacities but poor readability. In addition, their true accuracy is unknown, and it’s rare they can be recalibrated.

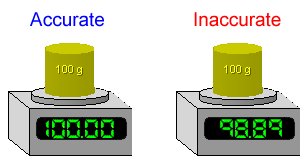

Calibration

Inexpensive scales usually can’t be recalibrated. This means that you get what you get and if the scale changes over time (or it’s not right to begin with) you have no way of knowing that it’s wrong and no way of correcting it.

Just because a scale displays a number doesn’t necessarily mean that the number represents the true weight of the object being measured. Better quality scales have better electronics, higher quality components and are held to higher quality standards by their manufacturers.

Better quality scales can be recalibrated, and smaller scales that can be recalibrated often come with a calibration weight. Calibration weights are precision weights that have been compared to a national standard and represent a physical truth. Not only can you compare the reading from your scale to the true weight of the calibration weight, you can correct your scale if it is off and can be recalibrated.

Measuring Error

Digital scales are most accurate when weighing near the middle of their range, meaning you are not trying to weigh an object that has a weight close to the lower limits of the scale.

Most scales have an upper weight limit to protect the load cell from physical damage if too much weight is applied. The readings are still accurate when weighing near the upper limit though.

Scales run into trouble when you try to weigh small amounts of material that are very close to the readability of the scale, because a scale’s precision is half the value of its readability. This is an extremely important concept to understand.

The scale’s electronics convert the voltage from the load cell (which is an analog signal), into a digital signal, which has to be rounded up or down to comply with the readability chosen for that scale.

If a scale has a 1 gram readability:

- Any weight that is less than 0.5 grams is displayed as 0 grams

- Any weight 0.5 grams or more is displayed as 1 gram

This is the precision of the scale. In the previous example, a scale with a 1 gram readability has a 0.5 gram precision, half the value of the readability.

An object that truly weighs 253.375219 grams would show:

- a weight of 253 grams when weighed on a scale with a 1 gram readability

- a weight of 253.4 grams when weighed on a scale with a 0.1 gram readability

Rounding always occurs, but by selecting a scale with a small enough readability, the error from rounding becomes small and insignificant.

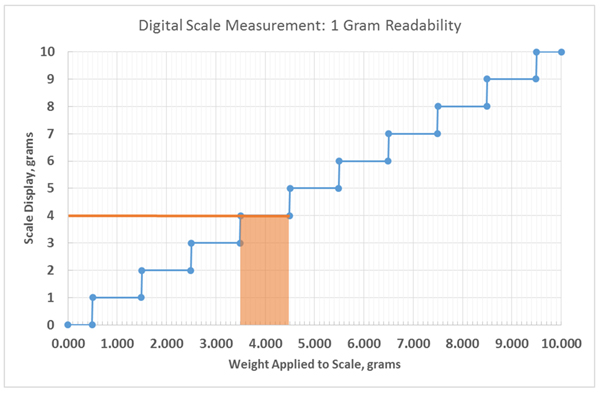

As another example, consider the scale graphed below:

Any weight that is 3.500 grams or greater but less than 4.500 grams will display as 4 grams on this scale.

There’s a loss of precision due to rounding, and this is where errors come from when trying to weigh an object that’s too light for the scale to accurately measure.

Error

Let’s use a common kitchen scale as an example. Often these have a 1 gram readability. As previously mentioned, trying to weigh out a small amount of pigment can create inaccuracy because of the inherent rounding that occurs.

The readability of the scale is 1 gram, so the precision of the scale is half of that, or 0.5 grams. Suppose you must weigh out 100 grams of pigment. As you add pigment to the scale, the readings change: 98 grams, 99 grams, and finally 100 grams are displayed. But do you really have exactly 100 grams of pigment? Probably not.

A better question is does it matter that you are off by a little bit? If the scale you are using has a 0.5 gram precision (half of its readability), then you may have weighed out 99.50 grams, 100 grams or 100.49 grams, and any of those would have been displayed as 100 grams on your scale. Since the variation is small compared to the total amount of pigment weighed, the error in color (since you’re weighing out pigment) is very likely small.

But suppose you use the same scale for creating a new color and try to weigh out only 2 grams of pigment. Your scale will display 1.5, 1.9, 2.2 and 2.4 grams all as 2 grams. The wide variation in actual weight as compared to the small total amount of weight is far more serious and will have a profound effect on the concrete sample’s color.

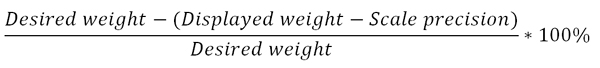

Here is the formula to calculate error:

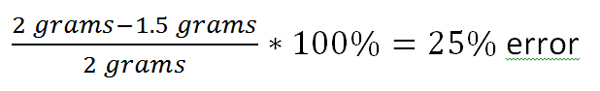

Let’s use the last example to calculate the magnitude of the error: If you had wanted to weigh out 2 grams of pigment but actually only weighed out 1.5 grams (but you didn’t kow it because the scale could only display 2 grams), your maximum error would be:

25% variation in pigmenting will have a profound effect on your colors!

If you wanted to weigh out exactly 100 grams of pigment on that same kitchen scale with a 1 gram readability (and a 0.5 gram precision), the error would be:

A 0.5% variation in pigmenting probably will not affect the appearance of your color samples.

So you can see how the error due to rounding drops to insignificant levels when you’re measuring weights much larger than the readability (and therefore the precision) of the scale.

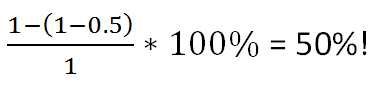

The greatest error comes from measuring the least amount of weight the scale can display, or in this case, 1 gram. In this instance the error would be:

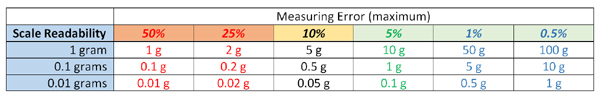

But if you weighed 10 grams on this same scale, the error would drop to 5%, a value that is much less significant and likely to be unnoticeable in most cases.

Recommendations

I recommend that you use scales with a readability that is at least 1/10th the weight of the smallest amount you anticipate weighing. That way the measuring error is never more than 5%.

For example:

- If you don’t plan on weighing less than 1 gram, you should use a scale that has a 0.1 gram readability

- If you plan on weighing 1/100th (0.01) of a gram, then you should use a scale with a 0.001 gram (or 1 milligram) readability.

Also, when selecting multiple scales, make sure the capacity of the smaller scales is at least 20 times the readability of the next larger scale.

For example:

- If your largest scale has a readability of 0.1 lb (about 45 grams), then the capacity of the next smaller scale should be at least 900 grams.

The importance of this issue recently came to light when I visited some fellow creative concrete professionals’ shops. I witnessed them using basic kitchen scales to weigh out pigments.

The Buddy Rhodes Concrete Products pigments I recommend are extremely powerful, often requiring much less than 1% loading to create a color, especially subtle earth tones. In fact, some of my new color formulas for the most popular earth tone colors use as little as 0.0165% of certain pigments.

To see just how precise this is, imagine you are making a small amount of concrete for samples, say enough mist coat to cover 1 square foot. This would require about 1.4 lbs of mist coat, and a 0.0165% loading of pigment in that amount of concrete would be only 0.044 grams of pigment. You couldn’t weigh this out on a scale that only had a 0.1 gram readability. You would need a scale that can weigh to the 1/1000th (0.001) of a gram.

The following scales are good choices and are available from www.itinscales.com and www.affordablescales.com:

Precision scale (preferred):

- At least 20g capacity, 0.001g readability

- Ohaus Scout Pro model SP-123 (120g x 0.001g) available at www.itinscales.com/oscout_pro.htm

- Price approximately $300

Precision scale (alternate choice):

- Ohaus YJ Carat Jewelry Scale model YJ-103 (20g x 0.001g) available at www.affordablescales.com/ohaus/yj-carat/

- Price approximately $150 to $200

Bench scale (preferred):

- At least 500g capacity (double that if only one bench scale is used), 0.1g readability

- Most of the Ohaus Scout Pro model SP-601 (600g x 0.1g) available at www.itinscales.com/oscout_pro.htm

- Price approximately $250

Bench scale (alternate choice):

- Ohaus Navigator Scale model NV 1101 (1100g x 0.1g) available at www.affordablescales.com/ohaus/navigator-nv/

- Price approximately $275

Floor scale (preferred):

- At least 150 lbs capacity, 0.1 lbs readability

- Most of the Ohaus Defender 3000 platform scales at www.itinscales.com/ohaus_defender.htm

- Price approximately $450 to $590

Floor scale (alternate choice):

- Ohaus SD Compact bench shipping scale, model SD 75 (165 lbs x 0.1lb) available at www.affordablescales.com/ohaus/sd/

- Price approximately $200

Equipping your shop with proper scales seems expensive, but it will save you money in the long run by enabling you to craft precisely colored, high quality creative concrete projects with confidence.