A few months ago, I wrote an article about installation, and I mentioned in there that you should use flexible caulk for seaming, not rigid epoxy, to allow for stress relief in case of slight movement of the slabs.

The other day, I witnessed a clear illustration of this when I visited a client from over 12 years ago. He was doing some renovations, and wanted me to take a look at “a few minor chips and scuffs”.

The surface had indeed held up very well for over a decade, but the biggest issue I saw when I arrived was that one of the slabs which extended out into a long cantilever over a book shelf had shifted a bit.

This original installation photo shows the large, irregularly shaped slab with drainboard and cantilever over a bookcase. The left side of the slab extends in the back to the center of the faucet, and in the front about 3 inches in front of the sink. The right side of the slab has a “puzzle piece” seam that zigzags back from the right side of the dishwasher to the right side of the cantilever.

That slab shifted about 1/8 inch towards the back, probably due to settling of the bookcase. The back side of the slab also cantilevers about 12 inches beyond the back of the cabinet, and therefore tends to cause tilting towards the back.

This will be super easy to fix! If I had put rigid epoxy in those seams, however, I would have a real problem on my hands. Instead of opened seams, there would be cracks in the concrete.

The client was still happy enough to serve me smoked salmon, champagne, and homemade lemon cake.

These were the ideal concrete countertop clients. They love their concrete countertops because of the imperfections, and they reported, “Looking at our concrete countertops gives us joy every day,” even 12 years later!

They especially like the curved windowsill that extends behind the farm sink.

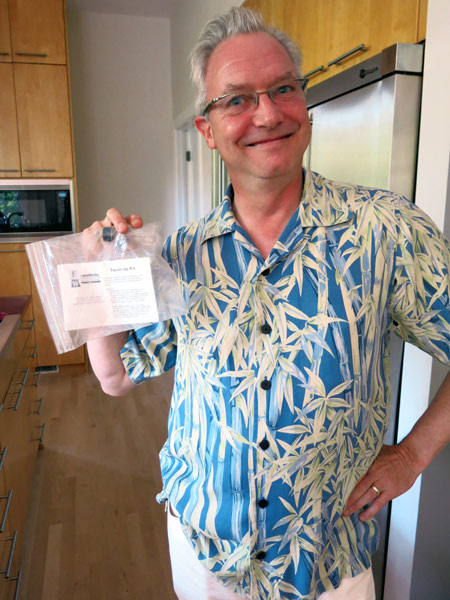

And, believe it or not, they still had their original FormWorks sealer touch-up kit in case of scratches. Now that’s a piece of history!