Cenospheres, also sometimes called microspheres, are used in a wide variety of materials, from paints and finishes to plastics and caulking. And although they have been used in concrete for some time, their use is not widely known. Cenospheres have a couple of uses in concrete countertop mixes, as:

- a workability enhancer and extra-fine aggregate, and

- a bulk filler and shrinkage reducer in cement grouts.

Cenospheres vs. Lightweight Expanded Aggregates

My last post discussed using lightweight aggregates like expanded clay, shale or slate to reduce overall concrete weight. Recall from that article that there are many ways to greatly reduce concrete countertop weight without complicating your mix design. Furthermore, while it is possible to create lighter weight concrete with cenospheres instead of lightweight aggregates, doing so presents such major mix design challenges that I do not recommend it as a weight-reducing strategy.

In theory, cenospheres can replace some of the normal-weight sand used in concrete. Cenospheres have a density that is less than water (averaging 0.7 vs. water’s 1.0); quartz sand particles typically have a density of about 2.65. This means that 1 pound of cenospheres takes up the same absolute volume as about 3.8 lbs. of sand.

Good concrete mix design practices use a variety of aggregate sizes. The broader the particle size range is, the better the particles pack together and the less cement paste is required to coat the particles and provide excess paste “lubrication” necessary for good workability.

Cenospheres’ particle sizes do vary. However, their extremely small size means that there’s a lot more surface area to coat than an equal volume of much larger sand particles. You will need too much cement to coat the tiny particles, resulting in a crack-prone mix.

The larger the particle sizes, the greater sand replacement percentage possible. Replacements of up to 33% of the sand with the largest-size cenopsheres have achieved concrete weights of around 124 lbs. per cubic foot versus 136 lbs. per cubic foot for normal concrete.

The advantage of cenospheres over lightweight aggregates is that they are essentially “invisible” in the concrete, even when it is ground and polished. However, given the mix design issues above, I do not recommend using cenospheres to reduce weight. They are useful in other ways: for workability and grout.

Workability Enhancer

A better use of cenospheres is workability enhancement. Cenospheres are very small spherical particles. As such they behave just like microscopic ball bearings in a concrete mix. Adding cenospheres to a conventional weight concrete mix will improve workability due to the ball bearing effect, and since the cenospheres are also structural aggregate, they improve concrete density and strength by providing better packing. In addition, the added fines improve trowelability and finishability. Typically dosages of 1% to 5% by weight of aggregate are added to a concrete mix to enhance workability.

Bulk Filler for Grout

Since cenospheres are very fine and generally light in color, they are ideal for use in the cement grout/slurry used to fill pinholes. Not only does the added bulk from the cenospheres increase the volume of grout without adding more cement, but also the fine aggregate gradation of the particles helps to reduce shrinkage. After all, grout is still a kind of concrete, so the same rules apply. Finally, the spherical shape makes packing pinholes easier and more effective because of the scrubbing action provided by the particles. And the spherical shapes are more likely to “roll” into small holes better than jagged or angular crushed particles. Typical cenosphere dosages for grout are around 10% to 30% by weight of cement.

So What Exactly Is A Cenosphere?

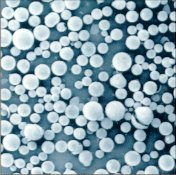

Like fly ash, cenospheres are naturally occurring by-products of the burning process at coal-fired power plants. Unlike fly ash though, cenospheres are lightweight, inert, hollow spheres comprised largely of silica and alumina and filled with air and/or gases. Since they are inert, they are not considered a pozzolan. And because they are very small and have high compressive strengths, cenospheres can be used as a structural lightweight filler.

Where Can You Get Cenospheres?

Now that you understand what cenospheres are and the great things they can do for concrete countertops, how do you get them? Most cenospheres are purchased in large volumes of truckloads or railcars for large industrial projects. So, they can be hard to find in small quantities for concrete countertops.

CCI recommends CenoStar Corporation for their easy to order small quantities and high grade cenospheres. You can buy quart quantities online at www.cenostar.com. If you’re looking for a good product for use in concrete countertops I recommend the EconoStar ES300. It has a maximum particle size of 300 microns (0.3mm). ES300 is light gray in color. If you need white cenospheres try the ChinaWhite CW300 for a similar particle size in a white cenosphere.