The size of reinforcing steel in a countertop is an important consideration. Concrete countertops that are made with rebar that is too large in scale for the slab thickness are susceptible to telegraph cracking.

When concrete shrinks due to drying out, high tensile stress levels develop around proportionally oversized reinforcing. These stresses cause cracks that run along the length of the steel. Smaller diameter reinforcing has less of an affect on the concrete, so the same amount of concrete shrinkage develops much less tensile forces, thus the likelihood of cracks caused by the steel itself drops dramatically. Because all concrete shrinks to some degree, and shrinkage occurs over a long period of time, the occurrence of telegraph cracking may not appear until long after a countertop is installed.

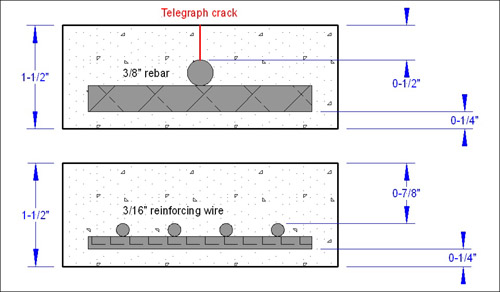

In addition, oversized reinforcing occupies so much space inside a thin countertop slab that there is very little cover between the steel and the slab surface. Generally, reinforcing is fabricated in a grid arrangement, with strands running along the length of the slab and overlapped strands running across the width of the slab. When stacked, larger rebar can take up half of the total slab thickness, while smaller rebar takes up much less space.

The sheer size of rebar that is too big places a significant amount of the steel closer to the visible surface of the countertop instead of down near the bottom of the slab. For example, a grid made from 3/8” diameter rebar held only 1/4” away from the bottom (the bare minimum cover for such a size) would place the top of the rebar at the midpoint of the slab, leaving only 1/2” of concrete cover between the steel and the visible surface. Contrast this with a grid made from 3/16” diameter wire held ¼” away from the bottom of the slab, and now there is 7/8” of concrete between the surface and the steel, a 75% increase in cover.

In addition to causing large stress concentrations in the concrete (and therefore increasing the likelihood of telegraph cracking), using oversized reinforcing actually decreases the load capacity of the concrete.

In the drawing above, the same concrete is reinforced with equal amounts of steel reinforcing (based on cross sectional area). The top drawing shows one piece of 3/8” (#3) diameter reinforcing steel while the bottom drawing shows four pieces of 3/16” structural reinforcing wire. The cross sectional areas are the same, so the tensile capacity of the steel is the same.

But because the four pieces of wire can be located lower in the slab, the load capacity of the wire-reinforced concrete is now 13% (lower reinforcing layer) to 78% (upper reinforcing layer) greater than the slab with the single #3 rebar, even though there is the same amount of steel in the concrete. In actuality, the structural wire has a higher strength than the rebar, so the difference in capacity is even greater.