Key characteristics that define a good cast-in-place concrete countertop mix are finishability and shrinkage resistance. However, these two characteristics are at odds with each other and must be carefully balanced in order to produce a good cast in place concrete countertop mix that is a joy to finish and does not curl or crack.

Other beneficial characteristics worth mentioning include workability and flexural strength. While high compressive strength is not necessary (though it is impressive), high quality concrete, often a byproduct of creating a high compressive strength mix, is also beneficial and desireable. Additionally, adequate work time, high early strength and a good appearance add to the list of desireable characteristics.

The two key characteristics that are very important, finishability and shrinkage resistance, are often determined by the aggregate gradation and the cement to aggregate proportioning.

Finishability, that is, the ease of trowelling the concrete into a smooth, even, high-quality surface relies on a sufficient amount of cement paste and very fine aggregate to create enough cream to trowel. Cream is the fine portion of concrete that is floated to the surface early in the casting process and is worked and reworked during trowelling.

Shrinkage resistance is also influenced by the water-cement ratio, by the cement paste content and by the amount of fine aggregate. Whereas finishability benefits from more cement paste and fine aggregate, shrinkage resistance benefits from less cement paste that has a lower water-cement ratio, since that is what actually shrinks. Minimizing the fine aggregate preserves workability when the cement paste volume is reduced, because fine aggregate (sand) has much more surface area than coarse aggregate, so more cement paste is needed to coat and separate fine sand than is required for a coarse blend of aggregates.

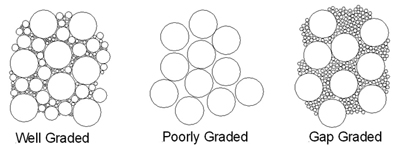

A poor cast in place concrete countertop mix would have large aggregate of one size, say 3/8″, mixed with fine sand. This is a case of “gap grading”. A good mix will have well-graded aggregate.

Click here for a free seminar including a specific cast in place mix design.