Curing. We all know it’s important, but what exactly is it, why is it important and what factors affect curing?

How Curing Works

Adding water to portland cement starts a chemical reaction called hydration. As hydration proceeds over time, the portland cement and water are transformed into beneficial calcium silicate hydrate (CSH) compounds.

These CSH compounds are the glue that hold the aggregates together, creating the hard, solid material we know as concrete. There are other compounds that form during the hydration process, but they are not responsible for strength.

Portland Cement + Water = CSH (provides strength)

Practically speaking, curing is simply the process of keeping the hardened concrete moist so that it can continue to gain strength. As long as free moisture and unhydrated cement exist inside the concrete, the strength, hardness and density will gradually increase.

As the concrete gets stronger and denser, its porosity decreases. This is important, because early on the concrete is much more porous than when it’s older and has hydrated longer. Porous concrete loses moisture to evaporation quickly, and this can lower internal moisture levels and stop hydration.

If hydration stops, the concrete dries out, and it stops gaining strength. This is why it is so important to cover your concrete right after casting and keep it moist. When concrete dries out, it dies, just as a tomato seedling would die if it weren’t watered.

The Role of Water in Curing

When concrete is mixed, all the water needed for full hydration is present in the mix design. Often contractors add more to the concrete than needed for hydration, to make the concrete more workable. This extra water is called water of convenience.

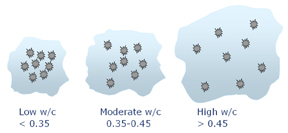

This water of convenience causes the cement particles to be too far apart to knit together into a strong matrix. It results in a longer set time and lower strength.

Cement particles that are too far apart can’t knit together.

Very powerful superplasticizers make it possible to remove almost all of the water of convenience, leaving a little bit more than just the water needed for hydration. This is the ideal blend of just enough water for hydration, but not so much water that the cement particles are spaced too far apart.

How Long Concrete Should Cure

It’s actually rare that concrete is cured until most of the cement is hydrated. This generally takes months or years to occur. Rather, the concrete is cured for as long as you need it to be to reach the desired strength.

The length of curing time can vary widely depending upon the structure or item made out of the concrete, the mix design, the concrete’s temperature and the desired strength at a certain time, to name just a few factors.

For concrete countertops, clients are not willing to wait 28 days for their concrete to be delivered. Because of this, mix designs tailored for concrete countertops have high early strengths so that the concrete can be cast, cured, processed and delivered in a week (or less).

For example, ordinary construction grade concrete often achieves a compressive strength of 4000 psi in 28 days. It’s not unusual for a mix design for concrete countertops to reach that strength in only 2 days. With some advanced mixes, this can be achieved in a matter of hours. So for a particular design strength, different mixes require different curing times.

How Temperature Affects Curing

Another factor that will influence the curing time is temperature. Colder concrete gains strength much slower than warmer concrete.

- At 3 days after casting, concrete cured at 45 degrees F only has about 70% the strength of the same concrete cast at room temperature (73 degrees F).

- In contrast, concrete cast and cured at 90 degrees F has about 10% more strength than concrete cured at 73 degrees F.

Over time these differences gradually become smaller, but often it’s the early (2 to 3 day) strength that is more important than the 28 day strength.

Polymer and Curing

Before the invention of polymer, glass fiber reinforced concrete was wet cured for 7 days. The addition of polymer to GFRC removes that requirement. Why? Because the polymer acts as an internal moisture barrier, keeping the water inside the concrete slabs so that hydration can continue.

Polymer can be used in other types of concrete countertop mixes as well, not just GFRC. For more information about polymer, see this article.

Conclusion

Tips for success:

- Don’t use more mix water than you have to

- Keep your concrete evenly moist for at least the first couple of days

- Use heat blankets or heat your shop if necessary

All this will allow your concrete to cure and strengthen. You will end up with higher quality concrete countertops and happier clients.