Fibers are used in concrete for a variety of reasons, but not all fibers do the same thing or have the same effect. The size, shape, material and amount of fibers used has a significant effect on the concrete. Using the wrong type of fiber, or not using enough, can lead to disappointment and a failed concrete countertop.

Fibers are generally added to concrete as shrinkage control (also known as secondary reinforcement; structural reinforcement is primary reinforcement). As the concrete sets and transforms from a workable paste into a hard solid, plastic shrinkage can occur. This is especially true in concrete slabs exposed to heat or wind. The matrix of fibers helps to stabilize the wet concrete and distribute the shrinkage stresses so that large cracks are minimized or eliminated.

Fibers are often advertised as capable of replacing welded wire mesh. This is true, but only when the welded wire mesh is used only as plastic shrinkage control. The confusion stems from the fact that welded wire mesh can also be used as structural (primary) reinforcement, while synthetic fibers cannot.

Most commonly used fibers are synthetic, either polypropylene or nylon, but some are natural, like cellulose fibers. None of these fiber materials are stiff or strong enough to provide any significant tensile reinforcement to uncracked concrete. And they simply stretch too much to do any good once the concrete cracks. After the concrete hardens, these fibers don’t contribute anything (nor can they) to resisting external structural tensile stresses.

There is a class of fibers that provides some resistance to external structural tensile stresses, but these are more esoteric and not generally necessary if you use proper steel primary reinforcing.

** This information applies to precast concrete countertops, not to GFRC concrete countertops (glass fiber reinforced concrete). In the case of GFRC, fibers do provide the primary reinforcing because there are so many of them, they are aligned two-dimensionally by rolling, and there is enough polymer in the concrete to provide a great deal more flexibility than normal concrete. Be aware though, GFRC is a system. You cannot take one element of GFRC and add it to regular precast concrete countertops and expect it to convey the properties of GFRC to the countertops. If you want to use glass fibers to reinforce your concrete countertops, you have to follow the GFRC system from start to finish; don’t just add glass fibers to your mix.

To learn more about using fibers as reinforcing, check out these articles on our blog:

- Glass Fibers: An Essential Component of GFRC Concrete Countertops

- Would Thinset and Fiberglass Cloth Make a Good Reinforced Concrete Countertop?

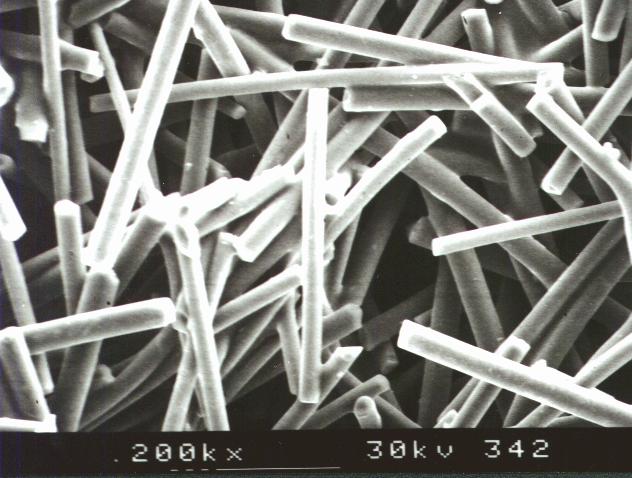

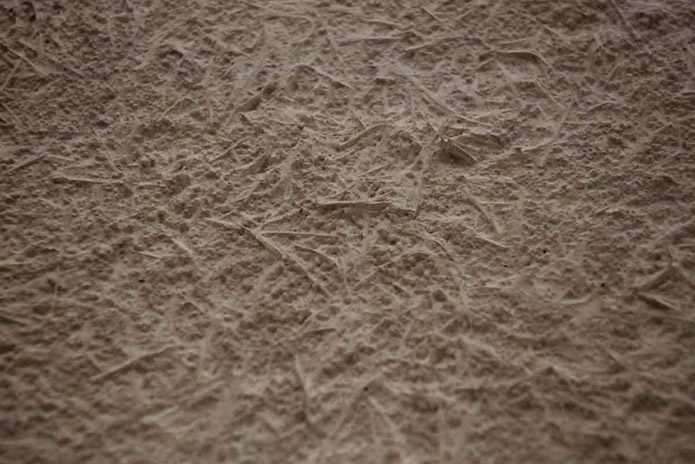

Structural AR glass fibers in GFRC: