Setting up your first “real” precast concrete countertop shop can be a bit daunting. A significant challenge is anticipating your present and future needs and finding an affordable shop that’s big enough to meet those needs. On the one hand, you don’t want to outgrow your shop too quickly, but on the other hand, it is critical to business success to keep your overhead as low as possible.

First, you should determine your target production volume, or how much concrete you want to cast at one time. Then it basically comes down to how big and how many casting tables you will need (and can afford) to accommodate this volume. Typical casting table sizes range from 4 x 8 to 5 x 12 feet. The bigger the table, the more efficient it is because more pieces can be formed on a single table. And the more square feet at a time your casting tables will accommodate, the greater your potential monthly output.

- For example, if your casting tables can hold 50 sq. ft., and you want to produce 200 sq. ft. of concrete per month, you will need to turn over the concrete from your casting tables every week. This is doable.

- If you were planning to produce 1,000 sq. ft. per month, 50 sq. ft. of casting table space would not be sufficient.

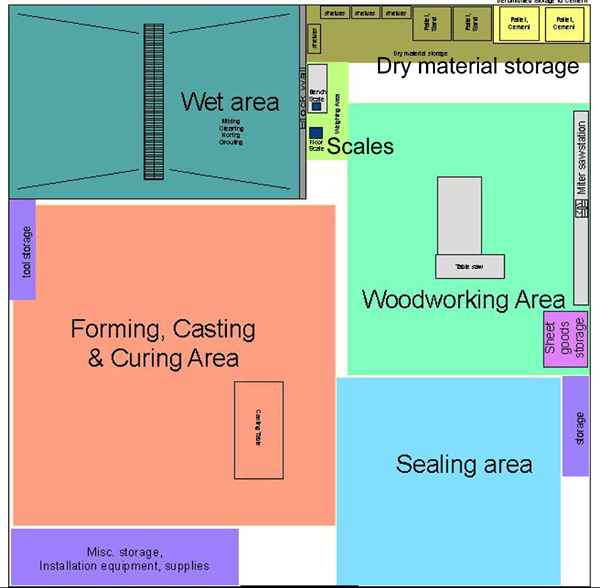

Also think about the various areas your shop needs to accommodate:

- Casting area (casting tables)

- Wet work (mixing, wet grinding, etc.)

- Dry work (woodworking, inspection)

- Sealing (I recommend a separate area to contain dust and fumes)

- Storage and machinery (for raw materials, tools for building forms, etc.)

- Office/showroom space

Here is a diagram of a possible layout of some of these areas:

An important part of setting up a shop is being organized from the start. When there’s a place for everything and everything’s in its place, you are more efficient. This is especially true in small shops, where you don’t have the luxury of dedicated spaces for everything. Floor space is at a premium, so make sure everything on the floor is on wheels so it can be moved easily and pushed out of the way when idle. This eliminates the need to build in working room around all stationary tools and tables, and that can save a lot of square footage.

Another important consideration is overhead. Think hard about how much more you can realistically sell to pay for that new shop. If you add additional overhead of $2,000 per month by renting a shop, and your net profitability target is approximately 25%, you will need to sell an additional $8,000 per month just to cover that new overhead. You should be turning away projects because you don’t have the space to do them before you consider moving into a larger shop.