As the old adage goes, all concrete cracks. What’s important to a client is that those cracks are not visible nor do they impact the performance of the countertop.

There are many types of cracks in concrete:

- Hairline cracks

- Structural cracks

- Map cracking or crazing

- Plastic shrinkage cracking

Cracks in Concrete Due to Stress

The first two types of cracks, hairline cracks and structural cracks, are signs of stress relief. A crack forms when tensile stress builds up in the concrete and exceeds the material’s capacity to resist those stresses.

Well-made concrete countertops should not develop structural cracks, however hairline cracks are possible and not a sign of poor quality.

Most large, structural cracks in countertops form because of flexing, either because a faucet was tightened too much or, as is the case in this picture, the house settled:

Flexural crack from house settlement:

Cracks in granite from over-tightened faucet:

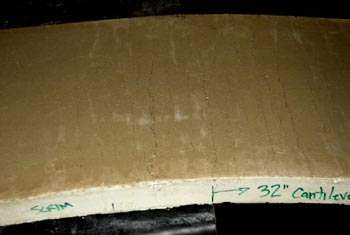

Multiple flex cracks in a overloaded cantilever beam:

Other Causes of Hairline Cracks in Concrete

Hairline cracks often occur because of shrinkage, either from drying or from heat. These types of cracks are more difficult to control because they generally occur near the surface, so reinforcing doesn’t help prevent them. The best preventative is to use a good mix design that has low shrinkage tendencies.

However, hairline cracks can and do occur, and are often located near areas of moisture (sinks and dishwashers), where dry concrete repeatedly absorbs moisture and then dries out. Over time this wetting and drying cycle will cause the concrete to crack, much in the same way a piece of steel will eventually crack if it’s bent back and forth enough times.

Hairline crack at sink:

Heat also can cause hairline cracking. Crock pots are a common source of heat related hairline cracks in countertops. Often it’s not the intensity of the heat but the length of time the concrete is heated. Crock pots don’t get very hot, but they sit in one spot for many hours. As the concrete heats it expands, and the more concrete that does heat up and expand, the greater the thermal stress that develops.

Generally it’s not just the heating that causes cracking, it’s also the subsequent cooling. As the concrete cools it shrinks, and it’s the shrinkage that causes cracking.

Thermal cracking in solid surface material from a crockpot:

Cracks in Concrete Due to Drying

Improper curing techniques and poor mix design, both of which cause premature drying, can cause cracks in concrete. The two main types of cracking caused by drying are map cracking (also known as crazing) and plastic shrinkage cracking.

Map cracking manifests as a web of fine, shallow cracks across the surface of the concrete. Because map cracking is limited to the surface, it does not pose serious structural problems. However, it generally is not a desirable look for concrete countertops and furniture and therefore can (and probably will) result in a re-do. Aesthetics are critical for concrete countertops and furniture, unlike structural concrete.

Plastic shrinkage cracking is much deeper, often to the mid-depth of the concrete. This should never occur in properly cured concrete. It is caused by the surface of the concrete drying too rapidly relative to the concrete below.

One of the easiest ways to prevent map cracking, besides basic good curing practices, is to use polymer in your concrete countertop mix. Polymer has a host of other benefits for concrete. For more information about polymer, please see the following resources:

- Technical article about How Polymer Works in Concrete Countertops

- Concrete countertop admix that includes polymer

- Podcast episode about polymer

How to Prevent Cracks in Concrete

Sometimes cracks are unavoidable, but some basic good concreting practices can make them less likely. Here are some best practices:

- Use GFRC, which has very high flexural strength

- Understand reinforcing principles

- Use polymer in your mix, as explained above

- Cure properly

By understanding concrete better, you will be more successful and less likely to experience cracking. Browse this website for more articles that teach you not just how, but why, and result in a deeper understanding of concrete and ultimately more success with concrete.