There are many different diamond polishers available of various sizes, speeds, electric versus air, etc. CCI has selected only the best polishers. Here are the polishers we recommend and why.

(See also this page for information about diamond pads, an extremely important component of achieving a high quality polish.)

Planetary Polisher: Inter-Tool DS3011

A three-headed planetary polisher will take your shop production to the next level. It makes polishing extremely fast, easy and foolproof. The best planetary polisher for concrete countertops is the Inter-Tool DS3011.

Click here for more information about the DS3011.

Pneumatic Polisher – The Alpha AIR-830

An air (pneumatic) polisher is an important tool for a concrete countertop pro to have. Because it is not electrically powered, you cannot be shocked by this tool if it gets wet while you’re polishing edges. It is also extremely lightweight and non-fatiguing.

The disadvantages of this type of tool are:

- It requires a large air compressor, which is expensive. However, the air compressor will also run several other tools in your shop, such as your GFRC backer sprayer, so it is a worthwhile investment.

- It is not powerful enough to run 7″polishing pads or 5″ and larger turbo cups. For this reason, we recommend you also have an electric polisher that you use for heavy duty grinding. See below for information about our recommended electric polisher.

We have found the Alpha AIR-830 to be the best air polisher in terms of power, production speed, versatility, durability and quality. Its powerful gearing, efficient turbine design and quality of manufacture mean it will power through thousands of square feet of polishing without needing much more than daily oiling.

(NOTE: Alpha offers both the AIR-830 and the AIR-850. The AIR-830 is most suitable for polishing concrete countertops. The AIR-850 spins too fast for 5″ and 7″ pads.)

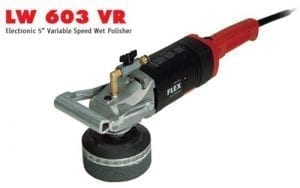

Electric Polisher: Flex LW 603 VR

We recommend that every concrete countertop professional have an electric polisher for heavy-duty grinding of large areas using 7″ diamond pads or aggressive grinding for large exposed aggregates using 5″ or larger metal bond turbo cups. Air polishers are not powerful enough for this job.

If you do not have an air compressor, you could choose to use an electric polisher exclusively. However, you still need an air compressor for spraying GFRC mist coat.