Basic Ingredients in Concrete

Three simple ingredients can be blended and proportioned numerous ways to make concrete, and the ratio of the water to the cement is particularly important.

- aggregate/sand

- cement

- water

The Importance of Water

In concrete, the single most significant influence on most or all of the properties is the amount of water used in the mix. In concrete mix design, the ratio of the amount of water to the amount of cement used (both by weight) is called the water to cement ratio (w/c). A w/c ratio of 0.4 means that for every 100 lbs of cement used in the concrete, 40 lbs of water is added. These two ingredients, cement and water, are responsible for binding everything together. The w/c ratio largely determines the strength and durability of the concrete when it is cured properly.

Implications of Water-Cement Ratio Variations

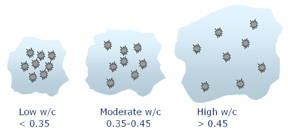

The simplest way to think about the w/c ratio is to think that the greater the amount of water in a concrete mix, the more dilute the cement paste will be. This not only affects the compressive strength, it also affects the tensile and flexural strengths, the porosity, the shrinkage and the color. The strength is reduced mostly because adding more water creates a diluted paste that is weaker. Think of it like over-diluting grape Kool-Aid. The more water you add, the weaker the Kool-Aid is.  Explained more technically, more water results in larger spacing of the cement particles. As the crystals grow during the chemical reaction between cement and water, they are too far apart to knit together and form strong bonds. This is why the concrete is weak.

Explained more technically, more water results in larger spacing of the cement particles. As the crystals grow during the chemical reaction between cement and water, they are too far apart to knit together and form strong bonds. This is why the concrete is weak.

More Problems Caused by High Water-Cement Ratio

Concrete with a higher w/c ratio is also more susceptible to cracking and shrinkage. Shrinkage leads to micro-cracks, which are zones of weakness. Once the fresh concrete is placed, excess water is squeezed out of the paste by the weight of the aggregate and the cement paste itself. When there is a large excess of water, that water bleeds out onto the surface. The micro channels and passages that were created inside the concrete to allow that water to flow and become weak zones and micro-cracks.

Typical Water-Cement Ratios in Concrete Mixes

Typical w/c ratios are as follows:

- Normal for ordinary concrete (sidewalks and driveways): 0.6 to 0.7

- Specified if a higher quality concrete is desired: 0.4

The practical range of the w/c ratio is from about 0.3 to over 0.8.

- A ratio of 0.3 is very stiff (unless superplasticizers are used).

- A ratio of 0.8 makes a wet and weak concrete.

Typical compressive strengths when concrete is properly cured are:

- 0.4 w/c ratio –> 5600 psi

- 0.8 w/c ratio –> 2000 psi

Mix Design for Concrete Countertops

Concrete countertops, sinks, fire features and furniture require vastly higher quality concrete than sidewalks or even foundations, in terms of both performance and aesthetics. One of the keys to the best concrete countertop mix design is to keep the water cement ratio very low. Typically concrete countertop artisans use w/c ratios of about 0.32%. The CCI from-scratch mix designs for GFRC and Precast adhere to this principle.

Conclusion

Using a low w/c ratio is the usual way to achieve a high strength and high quality concrete, but it does not guarantee that the resulting concrete is always appropriate for concrete countertops. Unless the aggregate gradation and proportion are balanced with the correct amount of cement paste, excessive shrinkage, cracking and curling can result. Good concrete results from good mix design, and a low w/c ratio is just one part of a good mix design. To have total confidence in your mix designs, use a calculator for a from-scratch mix design of GFRC or Precast.