There are several considerations to make when choosing a concrete countertop mix consistency. Some factors include the appearance of the finished piece, the forming and casting methods, and the complexity of the mold geometry.

Other factors that are not so obvious also drive the selection process. These can include the type of mixer that will be used, how the forms are assembled, the shrinkage tendency of the concrete and subsequent vulnerability or resistance to curling and hairline shrinkage cracks.

This article outlines the basic differences between two mix styles, stiff and fluid, in design, look and technique.

There are two basic types of mix consistencies: stiff and fluid.

A stiff mix is a versatile, all-purpose mix that can be adapted to a wide variety of looks, from a “solid” appearance, to a variegated/veined, or a terrazzo look. A stiff mix is typically made using only sand as an aggregate, and it has zero slump.

A fluid mix is a high slump mix that is more conventional in its ingredients, since it uses both fine and coarse aggregates. While coarse-aggregate based mixes are easy to make fluid, it’s vital that the fluidity is achieved by using superplasticizers and NOT by adding water. Concrete countertops require high quality concrete for aesthetic and long term performance. Using water to enhance workability instead of superplasticizers results in weak concrete that is prone to shrinkage, curling and cracking. Of course being disciplined with mix water applies to all types of concrete, but fluid concrete is more susceptible to water abuse.

Difference #1: The Look

Stiff Mixes

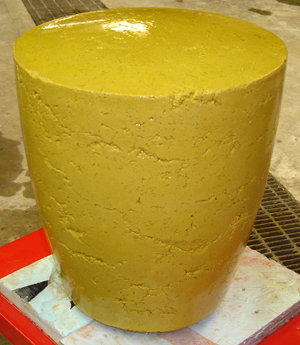

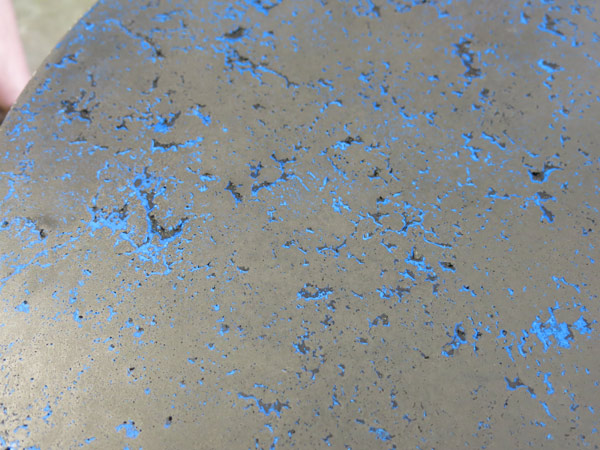

Stiff concrete mixes will always have voids in the cast surface. This is because the cement paste (and the mix as a whole) is so stiff that the entrapped air bubbles cannot escape. Often larger voids are irregularly shaped, and this tends to lend a more organic, stone-like look to the concrete.

The fact that the concrete is stiff and will always have air pockets can be exploited by purposefully introducing voids and patterned fissures. The resulting look resembles the veins in natural stone. Sometimes the voids are left open, but more often they are filled with contrasting cement grout. This highlights the voids and reinforces the resemblance to natural stone.

Buddy Rhodes is a master of this and calls it pressed concrete. Buddy will join us May 8-9, 2023 to teach exactly this technique during our class LEGENDS OF ROCK: The concrete concert of the century!

Fluid Mixes

Fluid concrete creates castings with very high surface quality. Edges are crisp and precise. Surface color and visual texture is smooth and even.

Concrete can be made fluid by using an appropriate mix design and superplasticizer, or a stiff mix can be made fluid by vibration. Either way the cast surface will very closely reflect the surface characteristics of the mold. If the concrete was cast against smooth, glossy plastic then the as-cast surface will be shiny and almost glass-smooth.

Fluid concrete mixes can sometimes have a few small pinholes, or if the casting is done carefully, no pinholes at all. If casting is not done carefully, they can have quite a lot of pinholes. There are several factors in preventing and dealing with pinholes.

- Use a defoamer such as Integrity UltraDense in your mix.

- Vibrate the concrete in the forms to help air bubbles travel up and out of the concrete.

- If any pinholes remain, fill them in with grout.

Difference #2: Casting Techniques

Stiff Mixes

Stiff concrete is placed by hand, often in small handfuls.The stiff nature of the mix allows the concrete to be packed onto vertical forms and place in thin layers.

Fissured concrete, sometimes called variegated or hand-pressed concrete, is placed so that air gaps between areas of concrete result in fissures once the concrete is demolded.

Fluid Mixes

Fluid concrete is often poured into forms, but it can also be placed by hand.

The next article will explore three more differences between stiff and fluid concrete countertop mixes.