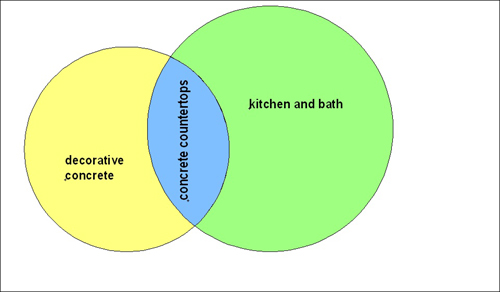

But wait, you say. Concrete countertops are decorative and they are made of concrete, so that makes them decorative concrete, right? Well, not exactly. All right, so what is decorative concrete, and how is it different from concrete countertops?

Decorative concrete encompasses a wide variety of surface finishes and treatments that are applied to or performed on a base of ordinary concrete. By and large, decorative concrete transforms or alters the appearance of plain concrete to enhance the look by adding color, patterns and texture. Other than stamped concrete, most forms of decorative concrete are applied to or performed on pre-existing plain concrete. These include acid staining, decorative overlays, scoring, etching, micro-toppings, sandblasting, dying and polishing. More often than not, decorative concrete includes flatwork, such as floors, driveways, sidewalks and patios, and also includes vertical walls, faux stone and trees.

Concrete countertops often include elements used in decorative concrete. The obvious are integral pigments, acid stains and polishing. They also can be stamped, etched, scored and sandblasted. It is for these reasons that many people include concrete countertops in with the decorative concrete industry. However, the appearance of concrete countertops is only a part of what they are, whereas the appearance is essentially everything with regards to many forms of decorative concrete.

If they don’t fall completely within the decorative concrete industry, where do they belong? The answer is in the kitchen and bath industry. After all, concrete countertops are countertops that just happen to be made out of concrete. All of the factors, considerations and expectations associated with other high end countertop materials directly apply to concrete countertops.

Concrete countertops are not floors that have merely been reshaped and elevated to sit upon cabinets. They should not be treated like floors, because countertops in general are held to higher standards than floors. Client expectations of what a countertop should look like, how it should perform and the general design and functionality are all very different from floors.

This is what happens when you don’t respect the differences

between floors and countertops.

The same standards clients hold granite and other natural stone countertops to are applied just as rigorously to concrete countertops. It is for these reasons that concrete countertops mainly belong in the kitchen and bath industry, because their primary purpose and functionality are as countertops. The decorative part, while important, is secondary. Concrete countertops are not decorative concrete. Concrete countertops are countertops.

Challenges Specific to Concrete Countertops

The reality is that making high quality concrete countertops is far from simple. There are two main reasons for this: countertops and concrete.

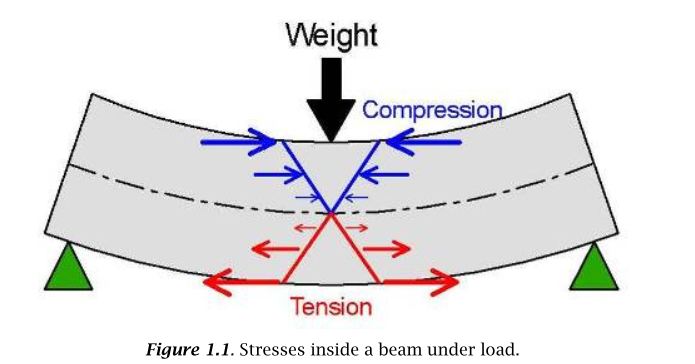

Any countertop professional knows that making high quality countertops involves many details that represent challenges in planning the project, making the countertop itself and installing the countertop. It’s important to recognize that countertops are beams. Without proper reinforcement, the countertop is doomed to failure.

Creating a high quality countertop begins with creating a high quality template. There are many templating techniques and even sophisticated computer systems to create templates. When templates are made, many considerations come into play, including planning overhangs, lining up seam locations with cabinet seams, placing sinks and faucets and more. Templating and planning all of these elements is a crucial step that most homeowners are either never told about or don’t understand the importance of.

Making any type of countertop involves a great deal of precision to ensure that the completed pieces match the template perfectly, and will therefore fit into the space. Every detail is important: the location of finished edges, the straightness and smoothness of the tops, the precision of the adjoining slab edges, even thickness of the slabs, etc.

Assuming the template is perfect and the countertops are precisely crafted to match the template exactly, the countertops still need to be installed properly. There are myriad important details that add up to a good installation: how to mount an undermount sink between the cabinet and the countertop, how to caulk between countertop and undermount sink for water-tightness and which caulk to use, how to secure the dishwasher, how to shim and adjust to make sure that seams are flush, and much more. This is after the slabs are safely transported into the kitchen or bathroom – that is a feat in itself that often requires specialized equipment.

Bottom line? Concrete countertops are in a league all their own, and it’s important to respect that. There is a great deal to understand about concrete and about countertops. Quite often people say, “But it’s all just cement and water, right?” Wrong. Dangerous oversimplifications and not taking the unique challenges inherent in concrete countertops often cause unsuspecting homeowners to bitterly regret their choice of material (and their contractors!).