This page contains frequently asked questions about Omega Concrete Countertop Sealer.

Top Questions About Omega

- Where can I find the instructions?

- How does Omega compare to Ovation?

- Can I put Omega over Ovation / Ovation over Omega?

- How can I increase the sheen of Omega?

- How do I prepare the surface to seal?

- Can I dry grind to prepare the surface for Omega? I usually do dry grinding instead of wet, or I’m doing a reseal in someone’s kitchen. Or I already dry ground!

- How can I reseal my old concrete countertops with Omega?

Overview

- How is Omega Concrete Countertop Sealer different?

- Where can I buy Omega Concrete Countertop Sealer?

- What is the coverage and cost per square foot?

- What equipment is required to apply Omega?

- What is the shelf life?

- What happens if Omega freezes?

- How do I know whether Omega has expired?

Comparison to Other Sealers

- How does Omega compare to Ovation?

- How does it compare to [other popular high performance urethane sealer]?

- I moved away from [other popular high performance urethane sealer] because of the excess rolling to get the finish to layout nicely in the lower to no dilution application steps. Does Omega have the same issue?

Appearance

- What sheens are available?

- Does Omega enhance the color of the concrete?

- Is there going to be a gloss version of Omega?

- How can I increase the sheen of Omega?

Performance and Stain and Scratch Resistance

- What test data do you have?

- How many total coats and how long did you wait for it to cure before the testing?

- Does it stand up to mustard?

- Is it grease/oil resistant?

- Will it prevent water marks?

- How does it perform with respect to scratches?

- Can scratches be repaired?

- How does it compare to [other popular high performance urethane sealer] when it comes to abrasion resistance?

- Why would I want to use a coating that might scratch if there are penetrating treatments out there that claim to provide stain and acid resistance?

- Can I put hot pots on it?

- Can I cut on it?

Where can it be used?

- Is it food safe?

- Do you recommend it for outdoor projects?

- Will Omega work on all concrete?

- Can Omega be used in wet areas such as sinks, tubs and showers?

- Will Omega adhere to glass and metal?

- Can Omega be used on fire features?

- How can I apply Omega to large vertical surfaces such as waterfall ends of a table or island?

- Can Omega be applied over a densifier?

- Can Omega be applied over acid stains?

- Can Omega be tinted with a color?

Maintenance

- How often does it need to be reapplied or resealed?

- How do I clean surfaces sealed with Omega?

- Can I bleach concrete countertops sealed with Omega?

Common Issues and Troubleshooting

- I have a technical issue with Omega. How do I get help?

- I applied the primer, and there are dark lines/blotches everywhere. What should I do?

- What if I get dust in the sealer? And if I don’t notice dust in the finish until the next day, and the surface is bumpy?

- There are chunks in Part A, and they’re getting stuck in the roller and on the surface. What should I do?

- When I opened Part A, there was a thick film on top. What should I do?

- I know Omega is supposed to be fine for wet areas, but I am seeing some water penetration. What’s going on?

- How’s the flash dry time compared to other similar sealers? With [other popular high performance urethane sealer], I find it hard to get it to lay out flawless on the less diluted coats on larger pieces without a third hand.

- What happens if I accidentally spill water on the sealer in the middle of the sealing process, for example after I’ve just finished the second of four finish coats?

Concrete Surface Preparation

- How do I prepare the surface to seal?

- Can I dry grind to prepare the surface for Omega? I usually do dry grinding instead of wet, or I’m doing a reseal in someone’s kitchen. Or I already dry ground!

Curing

- How long does it take for Omega to cure completely and gain its full performance?

- It’s been 24 hours, but my sealer still feels tacky/gummy.

Resealing and Compatibility with Other Sealers

- How can I reseal my old concrete countertops with Omega?

- Can I put Omega over Ovation / Ovation over Omega?

- I am not happy with the performance of [other sealer], and would like to reseal. Can Omega be applied right over our current sealer?

- I’m considering priming the concrete with [popular reactive treatment] followed by Omega top coats. The reasoning is that the [popular reactive treatment] will make the concrete itself stain/acid resistant, and Omega will provide an additional physical barrier that is also stain/acid resistant.

Q: How is Omega Concrete Countertop Sealer different?

A: Omega is a revolutionary new high performance urethane sealer that is also fast and easy to apply. Omega allows you to do in 2 hours what used to take 2 days with other urethanes. You’re done in a matter of hours, and never have to worry about callbacks again.

This is a unique two-component, water-borne aliphatic-polyurethane that is highly reactive and not dependent on humidity to cure. It rolls on quickly and easily without worrying about streaks or bubbles in the final finish. The finish is ready for light use as fast as one day after application.

Omega: Fast. Easy. Done. Your sealer woes are finally over.

Why Jeff developed Omega:

Q: Where can I buy Omega Concrete Countertop Sealer?

A: Click here for purchasing information.

Q: What is the coverage and cost per square foot?

A: A kit of 16 oz A, 8 oz B (24 oz) covers approximately 133 sq ft using 1 primer coat and 4 finish coats, and up to 267 sq ft if using 1 primer coat and 1 finish coat.

Cost is $129.99 per 24 oz, or $0.49 per sq ft at maximum coverage to $0.98 per sq ft at minimum coverage.

Q: Where can I find the instructions?

A: Click here for the Omega instructions. It is essential to watch and read the full documentation before applying the sealer.

Q: What equipment is required to apply Omega?

A: Omega is applied with foam rollers. It is important to use high quality foam rollers, because this will result in a better surface finish quality. If you purchase the Omega Full Kit, you will receive our ultra high quality German foam rollers as well as handles and measuring syringes. You may also purchase packs of foam rollers from the Sealers category in our online store.

Q: I have a technical issue with Omega. How do I get help?

A: First, please be sure that you have read this FAQ and accessed the extensive instructional videos using your login on our online portal. If you still have issues, in order to assist you properly we need complete and detailed information. Please fill out this form for Omega technical support.

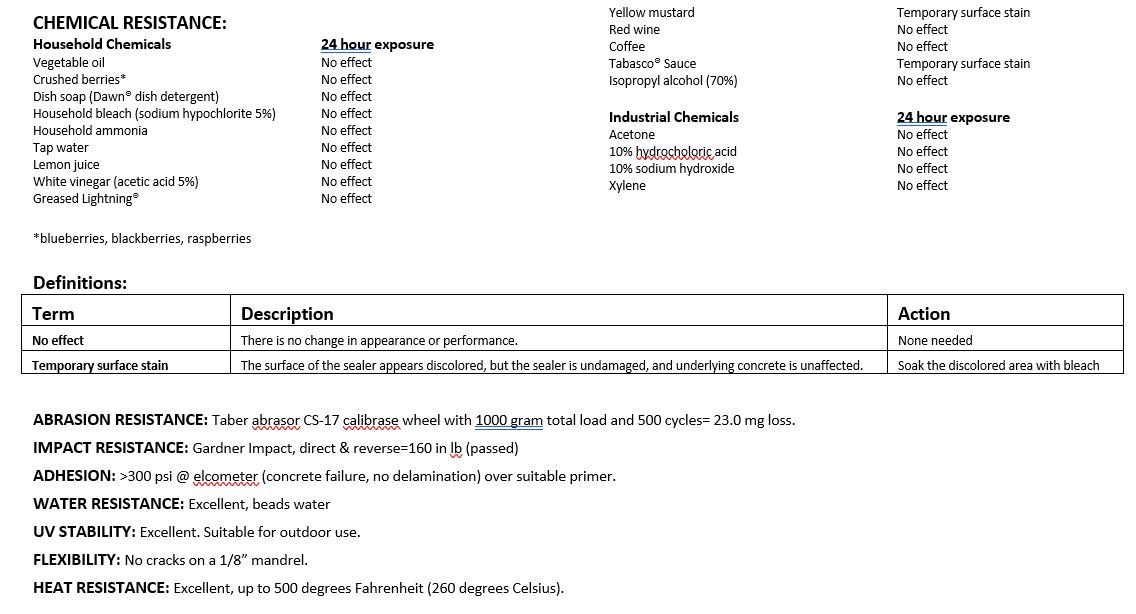

Q: What test data do you have?

A: Extensive testing for stain and acid resistance has been performed following the procedure explained here. Field testing and lab testing for UV stability, wet use, and freeze/thaw have been performed. Additional standardized tests for abrasion, impact resistance, adhesion and flexibility have also been performed. Here are the results.

Q: How many total coats and how long did you wait for it to cure before the testing?

A: Testing was done on 4 finish coats, when the finish was 2 weeks old. This represents typical long-term performance. Early performance was very good too, but hard to characterize, as the finish is still curing when it’s only a couple days old.

Q: Will Omega work on all concrete?

A: Yes and no. While Omega’s performance is not related to the kind of concrete it’s applied to, the appearance can be. Omega is primarily used by professional concrete countertop makers, who generally use concrete that is dense and relatively non-porous (like GFRC). Different concrete mix designs, casting techniques, curing regimens, surface processing techniques, environmental conditions, etc. will influence how well Omega is applied and how it looks.

In particular, very porous concrete can present challenges, showing dark lines that are sometimes interpreted as roller marks. Please see below for details on dealing with porous concrete.

Keep in mind also that Omega was developed specifically for professional concrete countertops and elements. It has not been tested on floors, which could range from conventional ready-mix concrete to highly polymer modified overlays to epoxy systems.

It’s strongly recommended to test Omega on a trial sample before sealing a real project for the first time. Practice in timing and application method is essential, because the outcome is often directly related to the skill and care of the one applying the sealer.

Q: Does it stand up to mustard?

A: Mustard is an extreme staining agent due to the coloring (often turmeric) and acidity. Mustard and Tabasco Sauce (a brand of hot pepper sauce) are the only substances that made a slight stain (a little color, not etching) after 24 hours, but that stain bleached out. Only the surface of the sealer stained – the concrete did not stain – and again, it was fixed easily with bleach. Please see the test results report above, and about halfway through the stain test performance video.

Q: Is it grease/oil resistant?

A: Yes, completely.

Q. Will it prevent water marks?

A: See below about water penetration.

Q: I know Omega is supposed to be fine for wet areas, but I am seeing some water penetration (darkening of the underlying concrete). What’s going on?

A: You might not have allowed Part A and Part to react for long enough before dilution. The instructions call for the mixture of Part A and Part B to rest for 5 minutes prior to dilution. This is called “induction time”, and it is important to the chemical reaction that must occur to give Omega its top performance.

It is critical that you allow a full 5 minutes of induction time, because shorter induction times result in a higher likelihood of water penetrating the cured sealer.

Even with an induction time of 5 minutes, it is possible to see water penetration, but it dries out on its own. If this is a concern, allow the area to dry out completely, then thoroughly dry scuff-sand the surface with 220 grit sandpaper and remove all sanding residue before applying at least one new finish coat.

Additional coats will definitely help with water penetration resistance, but be aware that Omega is a breathable finish, and the transmission of water through the finish is an inherent characteristic that makes using it in outdoor situations possible.

Q: Can Omega be used in wet areas such as sinks, tubs and showers?

A: Yes. Nothing special needs to be done, other than to use at least 3 finish coats.

If you are using in a tub and are concerned about slip resistance, you can add an anti-slip additive such as:

- www.concretenetwork.com/slip-resistant-coatings/gritty-sealers.html

- www.homedepot.com/p/Seal-Krete-3-2-oz-Clear-Grip-Anti-Skid-Additive-402002/203002764

- www.homedepot.com/p/BEHR-Premium-Non-Skid-Floor-Finish-Additive-97024/202301601

A: Yes. Once Omega is cured it is completely food safe and inert.

A: Omega is highly reactive, which is what makes it so fast to apply. The shelf life is:

– 12 months from the date of manufacture in unopened containers properly stored at room temperature

– Up to 6 months from the date of opening in opened and resealed containers at room temperature with dry gas blanket (such as Smooth-On XTEND-IT) applied

– Frequent opening, exposure to high temperatures, or storage without dry gas blanket will reduce shelf life and may affect performance.

To maximize shelf life and product effectiveness, Omega should be stored in room temperature conditions. Do not store it in hot conditions (like a shop with no air conditioning) or in a refrigerator, and never let it freeze.

Q: How do I know whether Omega has expired?

A: As Omega nears the end of its shelf life, Part A will become gel-like in consistency. If you can mix Part A to liquefy it, you can still use it.

Here is how to tell whether Omega has expired:

Q: How long does it take for Omega to cure completely and gain its full performance?

A: Just like concrete, sealers need to cure. You wouldn’t expect your concrete to have full strength after only 24 hours – although it may be strong enough to handle, it will gain strength over time. Typically you should expect full cure of Omega within 4-7 days, depending on temperature. (Omega is not dependent on moisture to cure.) Most urethane coatings require similar timeframes.

Q: It’s been 24 hours, but my sealer still feels tacky/gummy.

A: While Omega does not depend on humidity to cure, it is affected by temperature, just like your concrete, or any chemical reaction. In order for Omega to cure quickly, it needs to cure under warm conditions continuously, so ideally leave the heat on in your shop. At recommended temperature of about 70 degrees Fahrenheit (21 degrees Celsius), the sealer can see light use in about 24-36 hours, it will be durable in about 72 hours, and full cure generally occurs within about 4-7 days.

When brand new Omega feels oily, then it feels tacky, then it’s a bit soft and rubbery, then it continues to harden. If you lightly sand with 320 sandpaper and the paper doesn’t gum up and you get white dust, Omega is hard enough to sand out any dust spots.

A: Matte only. However, to preserve the excellent performance of Omega but obtain a different sheen such as satin or gloss, you can simply apply Ovation over Omega. See this article for more information.

Please note also that Omega is very color enhancing See below.

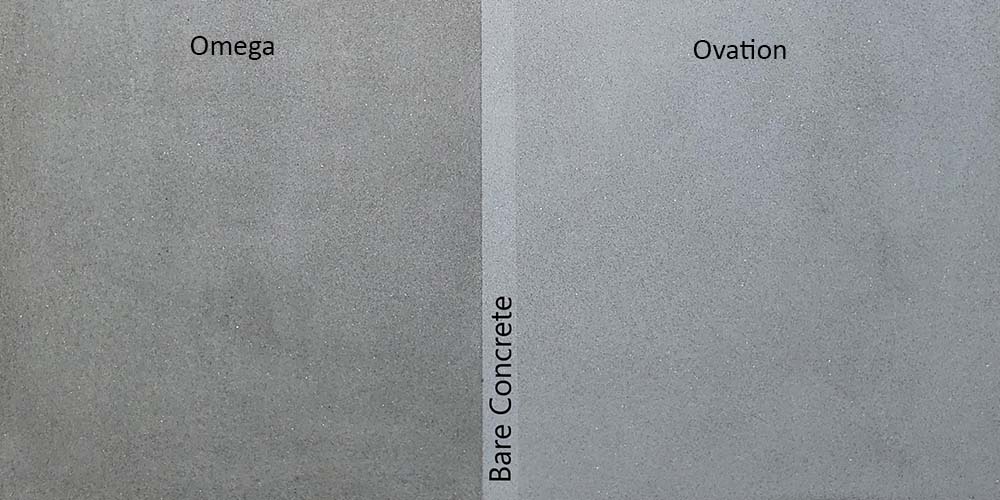

Q: Does Omega enhance the color of the concrete?

Yes. Omega is very color enhancing, meaning that it typically “wets out” the color of the concrete. (Color enhancement is a different property than the sheen of the finish.)

The degree of color enhancement varies depending upon the concrete and its history. How it was cured and processed, as well as the ingredients in the concrete, influence how close to or how far from water-wet the concrete will look. The color of the concrete also has a big effect on how much the concrete “wets out”: dark colored concrete will enhance far more than light colored concrete.

There is no way to predict exactly how much Omega will color enhance your concrete, because of the extreme variability in these factors. We recommend you seal a sample before using Omega on a full project.

Here is how Omega color enhanced a natural gray GFRC sample:

Q: Is there going to be a gloss version of Omega?

A: No. Omega develops its sheen by how it cures, not by a matting agent. Therefore it’s too hard to tinker with the chemistry to get a different sheen AND preserve the performance.

To preserve the excellent performance of Omega but obtain a different sheen such as satin or gloss, simply apply Ovation over Omega. See this article for more information.

Q: How can I increase the sheen of Omega?

A: To preserve the excellent performance of Omega but obtain a different sheen such as satin or gloss, simply apply Ovation over Omega. See this article for more information.

Q: How often does it need to be reapplied or resealed?

A: Never, unless you subject it to extreme abuse (like using your countertop as a cutting board).

Q: Do you recommend it for outdoor projects?

A: Absolutely. It is UV stable and fine for outdoors in all wet/dry and freeze/thaw conditions. It has been extensively tested on both lab samples and installed client projects for several months in challenging wet and freezing outdoor conditions. An alumnus in British Columbia, Canada, reports: “I use it for all my outdoor kitchens. It’s been raining, snowing, and freeze/thawing since and they are all perfect.” Lab tests over 6 months have shown zero effects from soaking, then freezing, then thawing many dozens of times.

A: Yes, up to 500 degrees Fahrenheit (260 degrees Celsius). It’s still a good idea to use trivets, because the underlying concrete may be affected by the heat even if the sealer is not.

A: No. There is no coating you should cut on, because unless a coating is made of diamonds, it will scratch.

Q: How do I clean surfaces sealed with Omega?

Maintenance and cleaning couldn’t be easier. Damp cloths, mild detergents and other water-based cleansers with neutral pH are all that are needed. Examples are 409, Fantastik, Windex, and Simple Green. Vinegar, bleach and bleach-based cleansers are acceptable.

Avoid harsh, acidic cleaners and solvents. Abrasive cleansers or scrubbers should never be used. These include Ajax, Comet, Brillo pads and 3M scrubbing pads, and all similar products. Abrasive cleaning products will scratch and damage the surface, compromising the sealer’s ability to protect the concrete.

Q: Can I bleach concrete countertops sealed with Omega?

A: Yes! Omega is completely impervious to bleach, so it is very easy to sanitize your concrete countertops simply by wiping them with bleach and a soft cloth.

Q: How does it perform with respect to scratches?

A: Omega has good scratch resistance. It will not scratch under normal use of simply placing objects on the counter. It will scratch if cut on with a knife, but unlike brittle finishes that fracture when scratched (that’s why scratches look white), Omega doesn’t show light cuts and scratches as a spiderweb of white lines.

A: Yes, Omega is easy for the homeowner to repair if scratches do occur. This means that you won’t have callbacks due to scratches.

For any sealer, you should provide your clients with a care and maintenance guide that specifies that they should not cut on the countertops, as well as what to do if scratches do occur, and your contract should include this information. This is part of setting expectations, which is important no matter what sealer you use.

Detailed instructions for scratch repair, as well as a care and maintenance guide, are available for download after purchasing Omega. You can provide these documents to your client. There is also an article about the basic process here.

Note that with any coating, it is important to repair scratches before they become a problem. If scratches occur and are left unrepaired, staining agents, acids or oil could get through to the underlying concrete and discolor or damage it.

Q: How does it compare to [other popular high performance urethane sealer] when it comes to abrasion resistance?

A: The abrasion resistance of Omega is very good, with a low Taber abrasor score (lower is better) – see the test results above. We don’t have comparable data for other sealers, and therefore cannot comment on which is better.

Q: Why would I want to use a coating that might scratch if there are penetrating treatments out there that claim to provide stain and acid resistance?

A: In our experience over the past 2 decades, no penetrating treatment has ever provided consistently satisfactory performance with respect to stain resistance, acid resistance and even water resistance. Only coatings completely prevent substances from ever touching the concrete, giving total protection.

It is important to test any sealer yourself (including Omega) to verify the manufacturer’s claims as well as to familiarize yourself with the details of its performance. We strongly recommend that you follow the rigorous stain and acid testing procedure before you put any new (to you) sealer on a client project – especially any treatment, because treatments allow substances to touch the concrete.

The debate between coatings and treatments has been raging in the concrete countertop industry for decades. Click here for a detailed article about this topic.

Q: How do I prepare the surface to seal?

A: See this article.

Q: Can I dry grind to prepare the surface for Omega? I usually do dry grinding instead of wet, or I’m doing a reseal in someone’s kitchen. Or I already dry ground!

A: NO! Never dry grind concrete that you plan to seal with Omega.

Please see this article for a detailed explanation of why, as well as 2 informative videos.

If you already dry ground the surface, it can be fixed. See this article.

It is entirely possible to wet grind in preparation for resealing on site in a kitchen or bathroom. See this article for how.

Q: I’m considering priming the concrete with [popular reactive treatment] followed by Omega top coats. The reasoning is that the [popular reactive treatment] will make the concrete itself stain/acid resistant, and Omega will provide an additional physical barrier that is also stain/acid resistant.

A: Be careful about applying treatments to concrete followed by any coating. Most coatings require clean, dry, bare concrete with enough microtexture (max 200 or 400 grit depending on the coating) to bond to. Omega, and likely most urethanes, almost certainly should not go over [popular reactive treatment] or any other penetrating treatment (densifier) with a lithium/potassium/sodium silicate or silicanate or siloxane chemistry. We have not tested Omega in these circumstances.

What you are trying to achieve is a completely impervious system that even if it scratches and staining agent/acid/oil gets through the scratches, the concrete underneath will not stain. But what you’re creating is a bonding problem.

The unfortunate truth is that there is no perfect sealer. You can choose stain/acid resistance, or you can choose scratch resistance. You can’t have both. As stated above, “In our experience over the past 2 decades, no penetrating treatment has ever provided consistently satisfactory performance with respect to stain resistance, acid resistance and even water resistance.”

We believe that stain/acid resistance is far more important. Click here for a detailed article about this topic.

Q: Can Omega be applied over a densifier?

A: Not without a lot of work, and even then it’s risky. See the answer to the previous question, and then read this article about resealing with Omega.

If you’re not resealing but making a new countertop, think about what you are trying to achieve by using a densifier, and whether it’s really necessary. Densifiers are typically used to decrease permeability and to make concrete harder for polishing. You don’t need to decrease permeability when you’re going to apply a completely impermeable coating. And you’re not going to polish concrete before applying Omega, because you’re going to stop at 200 or 400 grit. So densifiers make no sense with Omega or with any other coating.

Q: Can Omega be applied over acid stains?

A: Yes, if you’re talking about actual acid stains that work by penetrating the surface and reacting chemically with the calcium hydroxide in the concrete. In that case, Omega should adhere fine with very thorough surface prep, as is the case for all coating sealers. The acid stain must first be completely neutralized, and all residue scrubbed off. A “white towel” test will determine whether all of the residue has been removed or not. The concrete must then be well rinsed with water. The concrete should then dry for 24 hours, since all the cleaning pumps a lot of moisture into the concrete.

Please note that turquoise acid stains are vulnerable to moisture and can turn black over time because the color isn’t permanent in moist conditions (turquoise acid stains are copper based). We suspect that turquoise acid stains can’t deal with the chemistry or moisture of Omega. We have not tested Omega over turquoise acid stains and recommend that if you are going to attempt this, that you perform testing first.

Other “stains” may actually be pigmented coatings (e.g. Smith Paints), and Omega may or may not adhere to them. Excessive application of Buddy Rhodes Glazes can create adhesion issues (glaze to concrete and Omega to glaze). Using pigmented coatings and glazes under Omega should be tested by the end user, because application can vary so widely.

Q: Can Omega be tinted with a color?

A: While Omega can be tinted with pigments, it’s not a heavy-bodied product (meaning it’s a very low viscosity), so most of the pigment (especially powdered pigment) added to it will drop out of suspension, and very little of the color will remain to tint the Omega. Achieving a certain color is best done with the concrete itself or a standard concrete coloring technique such as acid staining or glazing. If you do want to color Omega, tint the finish coats, not the primer. Tinting the first three finish coats should brighten the color up, but it will not be opaque or monotone. The last finish coat should be untinted, so as to flow out smoother and achieve a more pleasing result.

Q: Will Omega adhere to glass and metal?

A: Glass and metal are popular decorative embedments in concrete countertops. Omega will adhere to properly prepared glass and metal such as stainless steel. Glass should be diamond-honed to a grit no finer than 200 to ensure good adhesion. Metal needs to be thoroughly cleaned and scuffed to ensure good adhesion. I recommend hand-sanding bare metal with a non-diamond abrasive such as silicon-carbide sandpaper to a grit no finer than 220. The metal should then be cleaned with acetone to remove residue, grease or other contaminants.

Q: Can Omega be used on fire features?

A: Yes, if the fire feature is properly designed (as ours are) to keep direct flame off the concrete, then neither the concrete nor the sealer are going to heat up too much, so this is a non-issue. Like most coating sealers, Omega does not stand up to open flame. Nor does concrete!

Q: How can I apply Omega to large vertical surfaces such as waterfall ends of a table or island?

A: Vertical surfaces can’t be primed the same way horizontal ones are, in that the surface is flooded with excess primer and it is allowed to soak in before being backrolled off. Since gravity will cause excess primer to run, priming a vertical surface like a waterfall leg involves rapidly applying less primer over the vertical surface.

The surface must be kept visibly wet until the concrete no longer draws in the primer. Load the roller with enough primer to wet the concrete but not so much as to create massive drips or runs that would waste the primer and just pool on the floor. Prime the vertical surfaces first before priming priming the horizontal surfaces. Start at the bottom and work upwards. This prevents marks from drips and runs.

Because you can’t soak the concrete for long, it’s best to apply at least 2 prime coats quickly, back to back, or until the surface is evenly saturated and well enhanced. Then let the primer flash off and apply finish coats as normal.

Q: How does it compare to [other popular high performance urethane sealer]?

A: That, as well as other company’s brands, are popular urethane based concrete countertop sealers with excellent performance. The advantage of Omega over the current urethanes is that it’s faster and easier to apply and get it to look good, and it still has the excellent performance. With concrete countertop sealers, both performance and appearance are essential – and it’s really nice if achieving both is quick and easy.

Q: I moved away from [other popular high performance urethane sealer] because of the excess rolling to get the finish to layout nicely in the lower to no dilution application steps. Does Omega have the same issue?

A: The main issue with all the other urethanes that Omega solves is exactly the excess rolling. Omega lays out on its own without streaks or bubbles. The key is not to *over* back roll it.

Q: I applied the primer, and there are dark lines/blotches everywhere. I thought this sealer was supposed to lay out easily with no roller marks. What should I do?

A: Your concrete is likely porous and absorbing a lot of moisture that is taking time to dry. It’s important to differentiate these marks left by moisture in the concrete from those created from primer that has prematurely dried before backrolling.

Areas that are absorbing more moisture will appear darker, and this appearance is temporary and will disappear when the concrete dries.

In contrast, areas in which primer dried prematurely before backrolling will appear lighter than areas that stayed wet before being backrolled, and those differences are usually permanent.

Here’s what’s going on if you have the former (absorbing more moisture) situation:

It is not uncommon for the concrete to appear blotchy and uneven during and even soon after the sealing process has been completed. Dark marks in the concrete (roller lines, puddle marks, drips, etc.) are due to excess moisture in the concrete enhancing those areas that are moister. And concrete that has very recently been wet before sealing can also exhibit uneven dark areas during and after sealing.

Dark roller lines and dark spots can remain in the concrete even after the sealing process is finished, and it usually takes at least 12 hours or more for them to fade and for the appearance to even out after the last coat of sealer is applied. (This of course assumes that the primer and finish coats were applied according to the directions, and didn’t dry before being backrolled.)

The process of priming involves soaking the concrete with primer until the concrete can no longer absorb any more. During priming, large amounts of moisture are pumped into the concrete, and how much moisture gets into the concrete depends upon its age, composition and porosity, as well as how long the primer is left on the concrete before backrolling. Areas where more moisture sat for longer times will appear darker, as water is an excellent but temporary color enhancer. The darker moisture spots/marks/lines usually don’t disappear during the 10 to 30 minutes needed for the surface moisture to flash off between coats.

The fresh primer coat (or coats, if more than one is used) holds the moisture in the concrete, and subsequent primer/finish coats help retain that moisture, resulting in a blotchy or streaky appearance. This is almost always temporary, as the moisture in the concrete evaporates over time.

Q: What if I get dust in the sealer? And if I don’t notice dust in the finish until the next day, and the surface is bumpy?

A: Dust is an issue in any shop, but Omega is very forgiving. If you notice dust, particles, hair, or fibers in the surface while sealing, they can simply be brushed off with your finger or a paper towel. The mark left by doing this will disappear on its own.

If you feel any roughness the next day after sealing, say if dust settled in there, simply go over it with 320 or 400 or 600 grit sandpaper very lightly and quickly by hand. There’s no need for machine sanding or buffing.

Q: There are chunks in Part A, and they’re getting stuck in the roller and on the surface. What should I do?

A: Because of the highly reactive nature of Omega’s chemistry, sometimes small amounts of material can cure with the tiny amount of air in the container and dry on the lid, causing bits of dried material to fall into the liquid. This is similar to what happens with paint cans when using ordinary household paint. It does not indicate any problem with the sealer and simply requires straining. Straining is recommended as a standard procedure, just like automotive finishes are always strained before applying.

Simply proceed with mixing Part A, Part B and water according to the instructions, then strain the mixture with a paint strainer before using it. The instructional videos contain detailed information about this procedure. [I’ll add red text to the instruction page now, and then we can post the video when you’re done with it.]

If you don’t notice the chunks before mixing and applying, no worries, pick them out and keep going, just like if you got dust or fibers in the sealer.

Q: When I opened Part A, there was a thick film on top. What should I do?

A: This is the same issue that can cause chunks. Simply remove and discard the thick film and proceed. The Part A container has a little extra material in excess of the 2:1 ratio to account for possible losses due to a film or chunks.

Q: What happens if Omega freezes?

A: You will know it! Part B shows no signs, but Part A becomes a hard, rubbery puck when frozen. When fully re-thawed, it has the consistency of gummy yogurt. During the winter, we put heat packs in the boxes, but you are responsible for selecting an appropriate shipping method that will get to you as quickly as possible, and for bringing the package inside promptly. No heat pack is capable of protecting against extreme freezing temperatures, and there are no refunds for frozen product. Please see our Order & Return Policy for more shipping details.

Q: How’s the flash dry time compared to other similar sealers? With [other popular high performance urethane sealer], I find it hard to get it to lay out flawless on the less diluted coats on larger pieces without a third hand.

A: Feedback from folks who have used that, and similar finishes, report that Omega lays out better and is less fussy. One main reason is that it requires less backrolling, so you’re not spending a lot of time trying to make a fast-drying finish look perfect. Omega lays out very nicely on its own, so you don’t need (or ever want to) over back roll it. In fact, it is best to leave any little bubbles because they pop on their own and become invisible.

Q: What happens if I accidentally spill water on the sealer in the middle of the sealing process, for example after I’ve just finished the second of four finish coats?

A: No worries, in the case of water spilled during the sealer process simply proceed with the next coat. However, if you spill water on the surface just after you have completed the sealing process, before the sealer has cured, you should blot up the water, because it will leave a dull or dark mark on the sealer. After the sealer has cured completely (usually after 4 days depending on temperature), it is completely impervious to water.

Q: I am not happy with the performance of [other sealer], and would like to reseal. Can Omega be applied right over our current sealer?

A: If the other sealer is a coating, likely yes. Most coatings just need to be scuff sanded (not sanded completely off), and then Omega applied. It has excellent adherence over a few other popular coatings we’ve tested. Please see this article for details.

Please note that Omega should NOT be applied over penetrating or reactive treatments.