Pozzolans are silicate-based materials that react with (consume) the calcium hydroxide generated by hydrating cement to form additional cementitious materials. They are often used in concrete countertop mix designs.

How Pozzolans Work

Why is consuming calcium hydroxide a good thing? Calcium hydroxide (lime) accounts for up to 25% of the hydrated Portland cement, and lime does not contribute to the concrete’s strength or durability. Pozzolans combine with the lime to produce additional calcium silicate hydrate, the material responsible for holding concrete together. By consuming the excess lime:

- The strength of the concrete is increased

- Its density is increased

- Efflorescence is decreased

- The propensity for alkali-silica reaction (reaction with glass) is decreased, or even virtually eliminated

Pozzolans as Cement Replacements

Typically pozzolans are used as cement replacements rather than cement additions. Adding pozzolans to an existing concrete mix without removing an equivalent amount of cement increases the paste content and decreases the water/cement ratio.

In other words, adding more pozzolans to a mix changes the mix proportions. Replacing some of the cement with pozzolans preserves the mix proportions.

Pozzolans replace cement pound for pound in good concrete countertop mix designs.

Types of Pozzolans

Depending upon the particle size, chemical composition and dosage, different pozzolans will affect the concrete strength differently and at different times during curing.

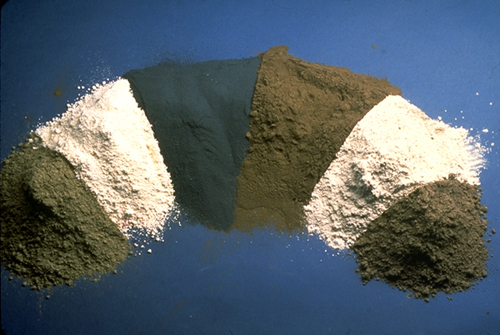

Left to right: Class C fly ash, Metakaolin, Silica Fume, Class F fly ash, Slag, Calcined Shale. From the Portland Cement Association

Left to right: Class C fly ash, Metakaolin, Silica Fume, Class F fly ash, Slag, Calcined Shale. From the Portland Cement Association

Typical pozzolans include:

- metakaolin

- silica fume

- fly ash

- slag

- VCAS (vitrified calcium alumino-silicate)

Reactivity of Pozzolans

- Silica fume is the most reactive pozzolan.

- Metakaolin is close to silica fume in terms of reactivity.

- Fly ash is less reactive, especially during the first few days of curing when less calcium hydroxide is generated.

Generally the finer the pozzolan particles are, the more reactive they are.

- Silica fume is the finest with most particles averaging 0.3 µm (microns)

- Metakaolin averages about 4 µm,

- Portland cement averages about 15 µm

- Fly ash averages about 70 µm.

How Pozzolans are Made

Many pozzolans are waste products from industrial processes. As such the color, quality, gradation and properties can vary and are not controlled.

- Fly ash comes from coal-fired power plants.

- Silica fume and slag come from some steel refineries.

VCAS and metakaolin are purposefully manufactured pozzolans. Quality, color and other characteristics can be controlled, so product consistency is greater. There may also be different grades available.

- I recommend VCAS by Vitro Minerals because it is white, recycled and enhances workability.

Pozzolan Blends

Most pozzolans are used individually, but blends of two or more different pozzolans can be used to take advantage of the characteristics each pozzolan offers. Typical examples are fly ash and silica fume blends, where the fly ash increases workability and particle packing and the silica fume helps with early strength and total strength development.

However, this is typically not necessary in concrete countertop mixes. I recommend a simple replacement of cement with VCAS.

Dosage of Pozzolan in Concrete Countertop Mix Design

The ideal dosage of VCAS is:

- For precast mixes, 15% cement replacement

- For GFRC mixes, 20% cement replacement

The dosage range of pozzolans depends upon the particular pozzolan selected:

| Pozzolan | Dosage | Effects |

| Fly ash: Class C | 15% to 40% | Increased workability. Early strength suffers with higher replacement doses |

| Fly ash: Class F | 15% to 25% | Increased workability. Early strength suffers with higher replacement doses |

| Slag | 25% to 50% | Increased workability. Early strength suffers with higher replacement doses |

| Silica fume | 5% to 10% | Significantly decreased workability |

| VCAS | 5% to 25 % | Increased workability |

| Metakaolin | 10% to 15% |

Decreased workability |

Additional References for Information about Pozzolans

- www.cement.org/cement-concrete/concrete-materials/supplementary-cementing-materials

- www.concrete.org/tools/frequentlyaskedquestions.aspx?faqid=688

- www.concrete.org/tools/frequentlyaskedquestions.aspx?faqid=689

- en.wikipedia.org/wiki/Pozzolana

- precast.org/2017/03/scms-in-concrete/?fs=pozzolan

- precast.org/2020/01/a-closer-look-fly-ash-slag-cement-metakaolin/?fs=pozzolan

- precast.org/2022/04/ground-glass-pozzolans-a-new-supplementary-cementitious-material/?fs=pozzolan