The quick answer is it makes the GFRC (glass fiber reinforced concrete) better. The long answer is more involved and explains what it does and why it is important in concrete countertops.

If you’d like to listen to a discussion of polymer, click here. Otherwise, read on.

The polymer used in GFRC plays an important role in the strength, appearance and durability of the concrete. Its primary purpose is to reduce the porosity of the concrete and hold the internal moisture within the concrete. This allows the pieces to be air cured and still achieve a 7-day strength equivalent to the same concrete wet-cured for 7 days.

Wet curing under plastic is necessary only for the first day (often overnight). Curing under plastic keeps the concrete moist while the polymer coalesces and forms what amounts to an internal curing membrane. The moisture retention also benefits long-term curing to improve the concrete’s mature strength.

The special polymer also has other benefits. It helps with casting and workability.

The polymer improves workability, aids in pigment suspension, and when sprayed, helps the mist coat cling to the forms.

Defoaming agents in the polymer help reduce entrapped air bubbles, reducing pinholes and improving the appearance of the cast surface. However, the use of additional defoamer at a dosage of about 0.1% of cementitious weight is recommended. See UltraDense for more information.

Lastly, polymer improves the concrete after the piece has hardened. After casting, the polymer helps reduce drying shrinkage cracks, improves the ductility, and provides freeze-thaw resistance.

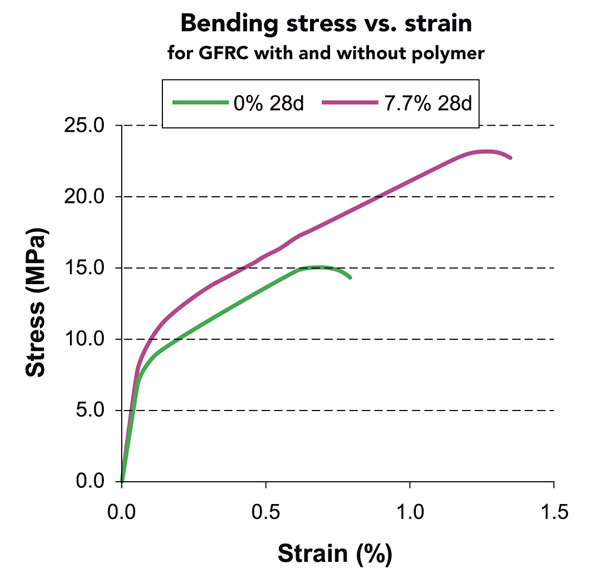

The following graph shows how polymer gives concrete more flexural strength and helps it tolerate more bending (strain) before failure.

- The pink line is higher, longer and extends to larger strain values than the green line.

- The GFRC made without polymer (green line) is weaker, more brittle and therefore cannot take as much bending or stress before failing completely.

Comparing the two curves shows that using the correct amount of polymer yields GFRC that is 50 percent stronger and that can take more than 50 percent additional bending strain.

Not all polymers are the same, even though the liquid ones are all milky-white liquids. GFRC polymer is specially formulated for the demands placed on GFRC products. The largest commercial application of GFRC is exterior building panels and facades, which are exposed to the elements in both desert and far northern climates. Yes, GFRC can be used outside!

The specialized polymer used in GFRC was developed and has been used for over 40 years. It is an acrylic thermoplastic copolymer emulsion that contains additives to improve and preserve the concrete it’s used in.

The polymer is UV stable, so it doesn’t degrade in sunlight. And unlike many decorative concrete polymers, it will not re-emulsify when it gets wet. (Most polymers used in decorative concrete function as bonding primers, so re-emulsification is a benefit.)

Polymers come in liquid and dry forms. Dry polymers are much easier to ship. They are also much easier to calculate in your mix formulas, because they are 100% solids. Liquid polymers are typically about 50% solids, so the water content must be accounted for in your mix calculations. See this article for more about how to calculate polymer dosage in GFRC mixes.

For dry polymer, there are a few standalone dry polymers on the market, but typically polymers are included in admixture blends for concrete countertops. Our Integrity PowerPack product comes blended with a revolutionary dry polymer. If you are purchasing another admix blend or all in one concrete countertop mix, check to make sure that it includes a polymer. As explained above, polymer has many benefits!

For liquid polymer, I recommend Forton VF-774 polymer from Smooth-On (formerly Ball Consulting).