“What is the best sand for GFRC?” is a common question. Sand is an important ingredient in GFRC that controls the appearance, workability, and strength of the concrete. Conventional concrete is more forgiving, but for GFRC the sand’s mineralogy, size and consistency are all important, especially when spraying mist coat.

The minimum criteria for sand are:

- Clean: No debris, no clay, no dirt, no sticks, no leaves, etc.

- Dry: No visible moisture or dampness. Moisture counts as mix water. It’s very difficult to determine how much water is in damp sand. Moisture and dampness can add a lot of water and weaken the concrete.

- Relatively fine grains: No chunks, no gravel, nothing bigger than about 1/16th of an inch (1.5mm). Smaller is better, but no powdery sand. Powdery sand is too fine.

- Light in color: The more colored the sand, the more it will affect the color of the concrete. Very light sand allows for brighter, cleaner, lighter concrete colors.

Sand for SCC or DIY GFRC

In the concrete countertop industry, many makers use a method they refer to as “SCC” or “direct cast” for GFRC. This method does not use a fiber-free mist coat or face coat followed by a fibrous backer coat, as in conventional or industrial GFRC. Makers simply mix a fluid backer mix and fill the forms with it.

Technically, this is not how real GFRC is done, and it makes the concrete weaker – see this article about fiber alignment. However, strength doesn’t matter much for small pieces, and the technique is so common in the concrete countertop industry that it bears mentioning here.

One great thing about this technique is that sand doesn’t matter much, other than in appearance. There is no need to find a special GFRC sand. You need only fulfill the minimum criteria listed above.

Mineralogy of Sand for GFRC

Most sand used for GFRC is quartz based, often called silica sand. Silica sand is an excellent choice because it’s hard, uniform, clean, very light in color, and relatively inexpensive if you can find it locally. Sand can also be crushed limestone, dolomite, marble, recycled glass, or other hard, natural or inert manufactured particles.

Understand that the color, hardness, and porosity will have an effect on your concrete. Some black slag blasting sand can negatively affect the concrete’s strength gain.

Silica blasting sand for GFRC

White quartz sand for GFRC

Sand Sizes for GFRC

Before we discuss the correct sand size for GFRC, you need to understand how sand sizes are measured. You may hear terms like “#30 blasting sand” or “#40 fine sand” thrown around, but what does this really mean?

Here in the United States, the gradation number (for example, “#40 fine sand”) is a size that relates to the average sieve size for that sand. Sieves are precision screens that separate sand into specific sizes. In the U.S., they’re classified by the US Mesh number. Similar to how sandpaper is graded, smaller sieve numbers (like a #20) have larger openings than sieves with higher numbers (#100), which have smaller openings.

US Standard Sieve Series

To illustrate this, look at the list below of sieve numbers and their corresponding millimeter sizes:

- #20 (0.850 mm)

- #30 (0.600 mm)

- #40 (0.425 mm)

- #50 (0.300 mm)

- #70 (0.212 mm)

- #100 (0.150 mm)

- #140 (0.106 mm)

You can see that the #20 sieve has openings that are 0.850 mm in size. The #100 sieve, on the other hand, has smaller size openings of 0.150 mm.

A sand is typically considered a “#30 sand” if most of the sand is finer than the #30 sieve (0.6 mm). In other words, most of the sand particles are smaller than 0.6 mm.

Here are the size guidelines for GFRC sand:

- Sand for GFRC should be smaller than 1 mm and larger than 0.1 mm (so #20 to #140).

- Sand sizes ranging from about 0.6 mm to about 0.2 mm are most suitable for GFRC (so #30 to #70).

- The best sand to use with Integrity PowerPack is in the 0.3 mm to 0.2 mm range (so #50 to #70). Because of the carefully tailored pozzolan blend in PowerPack, finer sands yield higher strengths and better flowability. We also recommend #50 to #70 for CCI’s from scratch GFRC mix formula.

- Sand should be relatively uniform in size. (Note that this is different than conventional concrete. In general, conventional concrete needs sand and aggregate sizes with a variety of gradations. See this article for more information.)

In summary, gradations of #30 to #70 are typically used for GFRC, with finer gradations of #50 to #70 being preferred.

Further guidelines are:

- Sand should be clean and dry.

- White colored sand is the most versatile because it does not affect the color of the concrete. Light colored sands are most common and have little effect on pigmented concrete.

- Here in the United States, suitable GFRC sands are often sold as blasting media for sand blasting. For these sands, the gradation number (for example, “#45 Fine Sand”) often relates to the average sieve size for that sand, rather than the maximum sieve size.

Which blasting sand to buy:

- Blasting sands in sizes ranging from #20 (coarse) to #80 (very fine) are excellent choices.

- Coarser sands (#20) tend to run off of vertical sections and bounce back when being sprayed.

- Very fine sands can be challenging to make flowable unless powerful superplasticizers are used.

The best and simplest way to determine whether sand you’re considering is suitable for your application is to get some, make a trial batch of concrete, and see how your concrete responds. Sand that’s too coarse or too fine may not let you cast your concrete in a way that suits your equipment or mix design. Look for sand that makes mixing and casting easy and that has a good price and appearance.

Technical Analysis of Sand Grain Size

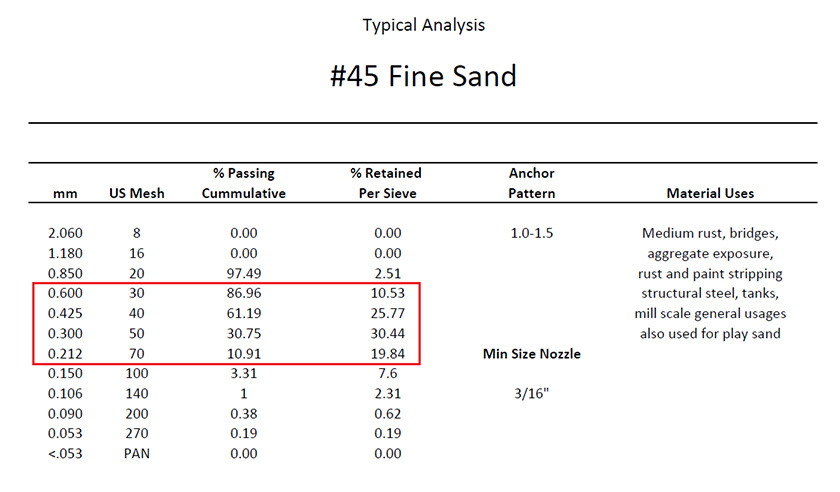

If you want to make sure a sand you’re considering buying is suitable for GFRC, you can ask the manufacturer for a grain size analysis. Here is a typical grain size analysis of a sand commonly used for GFRC:

Tables of data like this are called a grain size analysis, also known as a particle size distribution. They show the relative amounts of sand broken down into known particle sizes. Very uniform sands have most of the sand falling on one or two sieve sizes. Well graded sands spread the amount of sand over a wide range of sieve sizes. It’s common for GFRC sand to have most (about 80% or more) of the particles spanning 3 or 4 sieves, as is shown in the above example.

The sand in the above example is considered a #45 sand, since about half of the sand falls between a #40 and a #50 sieve. The first column (mm) and the fourth column (% Retained Per Sieve) are the two important pieces of information you’ll need to determine whether this sand is right for you. These tell you how much of each particle size (in mm) is retained (held back by) each sieve size. Generally, amounts less than 10% for any given sieve size are not that significant, and amounts less than 5% for any individual sieve are practically insignificant for our purposes.

As mentioned earlier, sand for GFRC should be smaller than 1mm, and larger than 0.1mm. In the example above:

- Less than 1% of the sand is smaller than 0.1mm, and this is perfectly fine.

- The largest particle size for this example sand is 0.85mm (or a #20 sieve), with only about 2.5% of the total weight of sand being that large. This is a small amount and won’t affect the concrete very much.

- The very finest sand size is only 0.053mm in diameter (a #270 sieve), but the amount held back is minuscule, at less than 0.2% of the total weight of sand.

- The majority of the sand falls between the #30 and the #70 sieves (within the red box), a very practical and desirable range.

Therefore, this sand is suitable for GFRC.

While the percentage of each sand size being retained on each sieve is interesting, what is more important is the range of sieve sizes retaining most of the sand. This is indicated by the red box. Sometimes blasting sand will be described with two numbers (30/50, for example). In this case it often means that the majority of the sand particle sizes fall between the #30 sieve (0.6mm) and the #50 sieve (0.3mm). This is a very small size difference, indicating this is a fairly uniform sand.

Finally, it’s possible to blend different size sands (say a #30 and a #70, for example), most people lack the tools necessary to accurately determine whether the blend is effective or if it accentuates too many of the common, overlapping particle sizes.