Fiber and polymer dosing for GFRC are not always straightforward calculations. This article explains exactly how to dose for concrete countertop mixes.

1. Fiber Dose

2. Polymer Dose

How to Calculate Fiber Load for GFRC

Unlike other admixtures, fibers are not dosed based on dry cementitious weight. A 3% fiber load means there are 3 lb of fibers added to 97 lb of non-fiber material to make 100 lb of GFRC backer.

Most GFRC fibers require at least a 3% dose to be effective, so we are using that in our example. However, Integrity UltraFibers are stronger than other fibers at only a 2.5% dose, and they flow better and show less.

Click here for more information about Integrity UltraFibers.

We first have to determine how much non-fiber material we have. Adding up our ingredients (everything but the fibers), we have:

33.4 lb sand + 26.7 lb cement + 6.7 lb pozzolan + 3.9 lb liquid polymer + 8.8 lb water = 79.5 lb of non-fiber material

So rather than having 97 lb of material, we have 79.5 lb of material. We can use ratios to find the amount of fibers to add:

- In English: 79.5 lb is to 97 lb as (unknown fiber quantity) is to 3 lb.

- In mathematical terms: 79.5 / 97 = x / 3.

To find x, just multiply both sides by 3 to cancel out the 3 on the right.

79.5 / 97 * 3 = 2.458 lb of fibers needed. (Rounded up to 2.5 in the example above.)

The total amount of backer would be 79.5 lb + 2.5 lb = 82.0 lb.

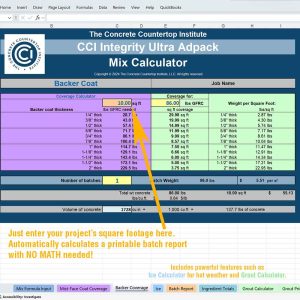

A much easier way to do this is to use the GFRC mix calculator.

How to Calculate Polymer Dose for GFRC

Dry Polymers

For dry polymers, simply dose as a percentage of total cementitious material. Follow the dosage recommended by the manufacturer.

For example, if the manufacturer recommends a 3.5% dose and you have 33.4 lb of cementitious material, you will need 1.2 lb of polymer.

You do not need to make any adjustments to your mix water.

Integrity PowerPack contains a revolutionary dry polymer blended with powerful pozzolans and a potent defoamer.

Integrity PowerPack makes your concrete denser, stronger, faster and easier. It contains a revolutionary dry curing polymer.

Click here for more information about Integrity PowerPack.

Liquid Polymers

Polymer is most often in a liquid form, so the calculations to figure the right amount of liquid polymer require knowledge about the solids content of the liquid polymer. Most commercial GFRC polymer is about 50% solids. Two widely used brands have 51% solids and 47% solids.

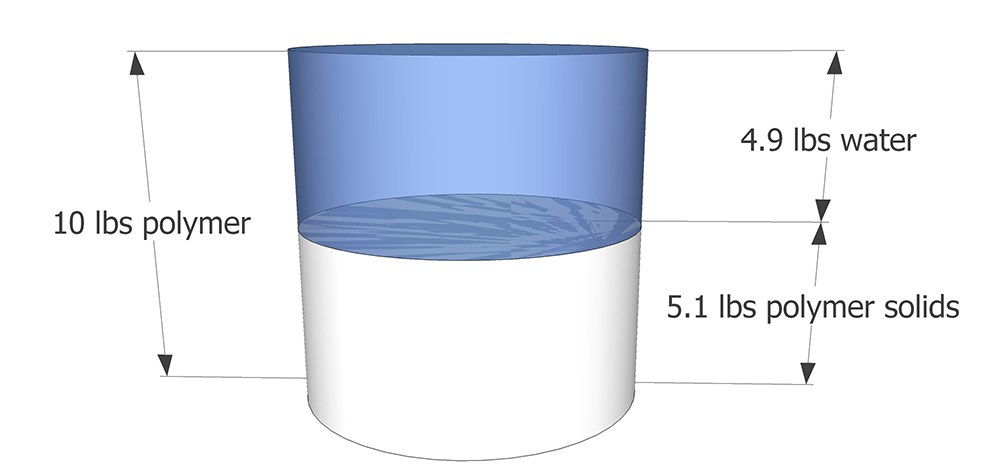

If we use an example of polymer with 51% solids, 51% of the weight of the liquid is polymer solids, and the other 49% is water. This water counts as part of the mix water used in the GFRC.

I will step through the calculations since this gets a bit complicated.

Let’s start with a typical commercial GFRC mix design that will make 10 sq ft of ¾” thick backer for GFRC:

- Sand: 33.4 lb

- 6% Polymer at 51% solids: 3.9 lb

- Water (.32 w/c): 8.8 lb

- Portland Cement (80%): 26.7 lb

- Pozzolan (20%): 6.7 lb

- 3% AR Glass Fibers: 2.5 lb (3% of total weight of non-fiber materials)

- Total weight per batch 82.0 lb

This mix design has 33.4 lb of sand and 33.4 lb (26.7+6.7) of total cementitious material. All admixtures (polymer solids, pigments, superplasticizer, etc.) are dosed based on the total cementitious material weight.

A 6% polymer solids dose means we need 33.4 lb * 0.06 (or 6%) = 2.0 lb of polymer solids (not liquid polymer). To calculate how much liquid polymer (what is poured out of the bucket) is needed, perform this calculation:

2.0 lb polymer solids / 0.51 (or 51% solids content) = 3.9 lb of liquid polymer

If you think about it, about half of the liquid polymer is water and the other half is solids, so about 2 lb of solids is contained in about 4 lb of liquid polymer.

Now to calculate the mix water:

- Calculate the total amount of water needed: 33.4 lb cementitious * 0.32 = 10.7 lb of water

- However, some of that water comes from the liquid polymer. So now we need to calculate how much water will come from the polymer we’re adding. We’ve already calculated that 3.9 lb of liquid polymer is needed, and that contains 2.0 lb of polymer solids, leaving 1.9 lb of water being contributed by the liquid polymer. (3.9 – 2.0 = 1.9)

- Now subtract that water from the total amount needed. 10.7 lb – 1.9 lb = 8.8 lb water to add.

Changing the w/c ratio alters only how much water we must batch out (more or less than 8.8 lb), it does not change the amount of liquid polymer needed.

The Easy Way: GFRC Mix Calculator

These calculations are complex but essential for correct GFRC mix design. They are here to give you a full understanding of GFRC mix calculations. It is far easier simply to use the GFRC mix calculator. It completely eliminates the need for math and formulas. All you have to do is enter the square footage (or meters), and it prints a batch report.